Measurement Systems Management

Master the essentials of Measurement Systems Management and elevate your organization’s precision, accuracy, and quality assurance practices.

Course Overview

The Pyzdek Institute Measurement Systems Management workshop is hands-on, workflow-based, and significantly different than typical Measurement Systems Analysis (MSA) courses. As it turns out, assuring data validity and establishing a baseline for Continuous Improvement requires a systematic error-proofed workflow that includes much more than a Measurement Systems Analysis like the AIAG GR&R method. In addition, most companies have a need to evaluate inspection processes that result in defect count, pass/fail decisions or other discrete results, a challenge that requires methods not typically covered in an MSA course.

This highly visual Pyzdek Institute course teaches a systematic 3-step approach to Measurement Systems Management including the knowledge, workflow and support materials needed to assure measurement system data are useful for important business decisions. The course content is suitable to the healthcare, plastics, food processing, machining, aerospace, automotive and other manufacturing industries. A Certificate of Accomplishment is issued to attendees that regularly attend and demonstrate a good understanding of the course content.

- Format: Instructor-led

- Level: Intermediate

- Location: On-site, Online or Hybrid

- Duration: 24 Hours

Pre-requisites

The course can be taught with JMP®, SigmaXL® or Minitab®, statistical software. For any software choice, attendees should have a good understanding of software fundamentals including navigation, menu structure, data integrity, annotations, and graphing. The course includes a 2-hour online session for those without statistical software experience.

To get the most out of the course, attendees should have their own PC, a recent version of the statistical software, a 2-way headset and a webcam. Two monitors are highly recommended.

Live, Instructor-led Training from Certified Master Black Belts

The Pyzdek Institute Measurement Systems Management course is delivered live by Certified Master Black Belts, who possess a wealth of experience in applying Lean Six Sigma methodologies and advanced statistical methods across a variety of industries. These seasoned experts not only hold the highest level of Lean Six Sigma certification, but also have a proven track record in leading successful process improvement initiatives.

They bring their practical knowledge to each training session, transforming complex theoretical concepts into actionable strategies. Their interactive approach ensures that participants are actively engaged, fostering a richer learning experience. They are adept at catering to different learning styles and can provide real-time feedback, making the learning process more personalized and effective.

In this course, you will be learning from the best, gaining insights from professionals who have successfully implemented the strategies they teach. With their guidance, you will be equipped to effectively apply statistical methods to reduce costs in your own organization.

Who is this Course Designed for?

This course is designed for R&D/Plant Engineers, Scientists, Supervisors, Managers, Technicians and Six Sigma Belts who need to qualify and maintain measurement systems and inspection systems.

Benefits to attendees

- A proven workflow-based system to properly manage measurement systems.

- Improved data quality and thus improved business decisions

- Exposure to many useful statistical principles

- Answer measurement-related auditor questions (FDA, IATF-16949, AS-9100, customer audits, 3rd party audits)

- Major contribution to Operational Excellence, quality award and similar programs

- Improved return on investment in statistical software licenses

Course Structure

| Course content | % of time spent |

|---|---|

| Hands-on exercises & interpretation of results | 80% |

| Basic principles | 20% |

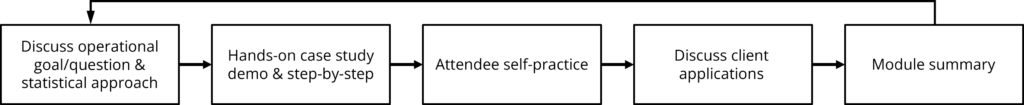

For both on-site and online, there are no lectures or PowerPoint presentations. Instead, the instructor uses the following steps for each agenda module:

Examples of Subjects Covered

- Fundamental statistics relevant to MSM

- The 3-step MSM workflow: Work-Evaluate-Decide

- The MSM Workflow Record

- Control charts to establish a measurement system baseline.

- Stability (time, temperature, seasonal and other effects)

- Bias and Linearity

- Manufacturing Specifications that compensate for measurement uncertainty

- Repeatability & Reproducibility

- The Gauge Performance Curve and how to use it to judge inspection systems.

- Measurement system tips, tricks & pitfalls

Schedule options

- Four 4-hour segments spread over 4-5 weeks is recommended for online delivery.

- Two 8-hour sequential days are recommended for at-site delivery.

- Other scheduling based on customer need.

The Pyzdek Institute’s Measurement Systems Management course is also available for groups. Whether you are looking for online or onsite training, we are pleased to accommodate your needs and customize the course to your organization.

Ready to Refine Your Process with Expert Measurement Systems Analysis?

If the Measurement Systems Management course resonates with your quest for improved accuracy and precision, or fits your team’s ongoing development strategy, we would be delighted to discuss it further. Our Certified Master Black Belts are on hand to help you learn the skills needed to effectively manage measurement systems and drive process improvement in your organization.

We acknowledge that each organization is unique, and hence we are here to offer tailored advice and answer all your queries. Whether you’re curious about the course content, scheduling, software requirements, or how this training can benefit your specific role or industry, our team is eager to assist.

Contact us today to start your journey towards mastery in Measurement Systems Management.