Your cart is currently empty!

Cost Reduction Methods for Assembly Industries

Elevate your skills in process improvement with a focus on assembly industries.

Course Overview

Cost Reduction Methods for Assembly Industries is a hands-on, workflow-based course. It covers key fundamentals, reinforced with sports equipment, aerospace/automotive sub-assembly, consumer goods and other assembly-related case studies, error-proofed workflows, and hands-on practice.

People with intermediate-level statistical experience should consider a more detailed alternative: the Pyzdek Institute Measurement Systems Management, Statistical Process Management and Process Optimization & DOE workshops, in that order.

Course attendees will learn to approach tough assembly challenges with a sequential, error-proofed method designed to avoid unnecessary expense, avoid common pitfalls, and improve processes in a cost-effective manner. At the end of the course, attendees will have the ability to gather the process insight needed to make good technical and business decisions. A Certificate of Accomplishment is issued to attendees that regularly attend and demonstrate a good understanding of the course content.

- Format: Instructor-led

- Level: Beginner

- Location: On-site or Online

- Duration: 32 Hours

Topics covered include:

- Lean Process mindset

- Statistical mindset

- Data integrity

- Exploratory Data Analysis (EDA) of existing process and customer data

- Analysis of data from customers and Subject Matter Experts

- Measurement Systems Analysis (MSA)

- Process Behavior Studies and Capability Analysis (SPC/PCA)

- Predictive Analytics

- Process Optimization

Pre-requisites

The course can be taught with JMP®, SigmaXL®, BlueSky® or Minitab®, statistical software. For all software options, attendees should have a good understanding of software fundamentals including navigation, menu structure, data integrity, annotations, and graphing. The course includes a 2-hour online session for those without statistical software experience.

To get the most out of the course, attendees should have their own PC, a recent version of the statistical software, a 2-way headset and a webcam. Two monitors are highly recommended.

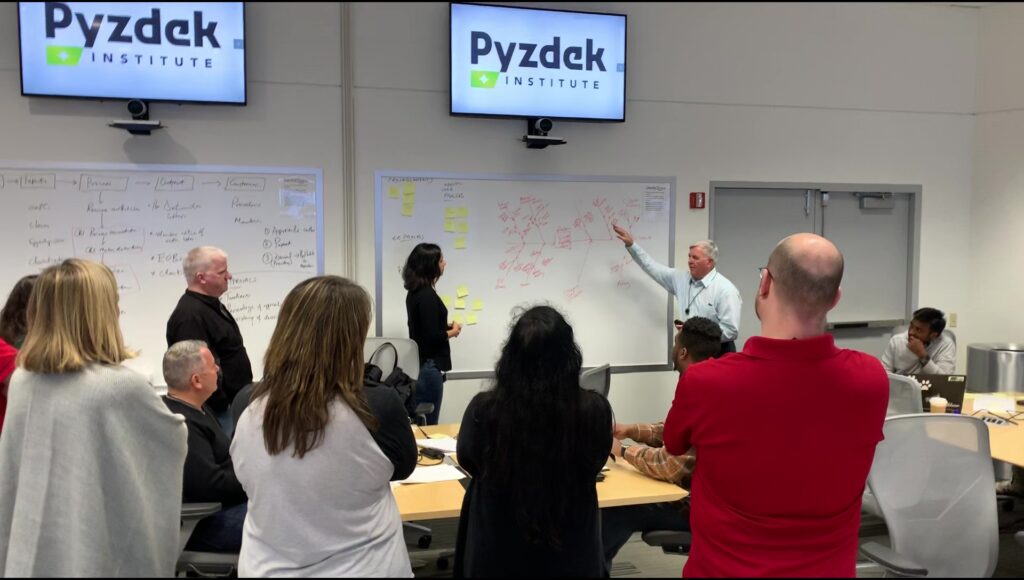

Live, Instructor-led Training from Certified Master Black Belts

The Pyzdek Institute Cost Reduction Methods for Assembly Industries course is delivered live by Certified Master Black Belts, who possess a wealth of experience in applying Lean Six Sigma methodologies and advanced statistical methods across a variety of industries. These seasoned experts not only hold the highest level of Lean Six Sigma certification, but also have a proven track record in leading successful process improvement initiatives.

They bring their practical knowledge to each training session, transforming complex theoretical concepts into actionable strategies. Their interactive approach ensures that participants are actively engaged, fostering a richer learning experience. They are adept at catering to different learning styles and can provide real-time feedback, making the learning process more personalized and effective.

In this course, you will be learning from the best, gaining insights from professionals who have successfully implemented the strategies they teach. With their guidance, you will be equipped to effectively apply statistical methods to reduce costs in your own organization.

Who is this Course Designed for?

This course is designed for Engineers, Scientists, Six Sigma Belts, Supervisors, Managers and Technicians who need to solve difficult assembly & packaging problems, optimize existing assembly processes, or set up new processes.

Benefits to attendees

- Use error-proofed workflows to improve processes, gain new process knowledge, increase corporate profits, and avoid common DOE pitfalls.

- Minimize the cost of data-centric process improvement work.

- Analyze data and interpret results in group discussion.

- Multiply the effectiveness of Lean-based process improvement.

- Learn many useful statistical principles.

- Improve return on statistical software and past/future training investment.

- Two hours of free course content support after the completion of class.

Course Structure

| Course content | % of time spent |

|---|---|

| Hands-on exercises & interpretation of results | 80% |

| Basic principles | 20% |

Examples of Subjects Covered

- The statistical mindset and The Great Mathematical Quandary

- EDA tools: variability chart, scatter plots & matrices, Principal Component Analysis, etc.

- Understanding the customer: analysis of survey and Subject Matter Expert data

- AIAG Gage R&R or Wheeler’s EMP method

- IMR, XBar-R and Short Run charts for Process Behavior Studies, Capability indices

- CART® Classification & Regression (Minitab) or Partition Analysis (JMP)

- Fundamentals of Factorial, Response Surface & Definitive Screening experiment design

Schedule options

- Eight 4-hour segments spread over 4-5 weeks is recommended for online delivery

- Four 8-hour sequential days are recommended for at-site delivery

- Other scheduling based on customer need

Ready to Unlock Cost Savings in Your Organization?

If our Cost Reduction Methods for Assembly Industries course sounds like the perfect fit for you or your team, we’d love to chat further. Our Certified Master Black Belts are ready to help you learn the skills needed to drive cost reductions and process improvement in your organization.

We understand that every organization is unique, so we are here to provide personalized guidance and answer any questions you may have. Whether you’re curious about the course content, scheduling, software requirements, or how this training can benefit your specific role or industry, our team is eager to assist.

Contact us today to start your journey towards mastery in cost reduction methods.