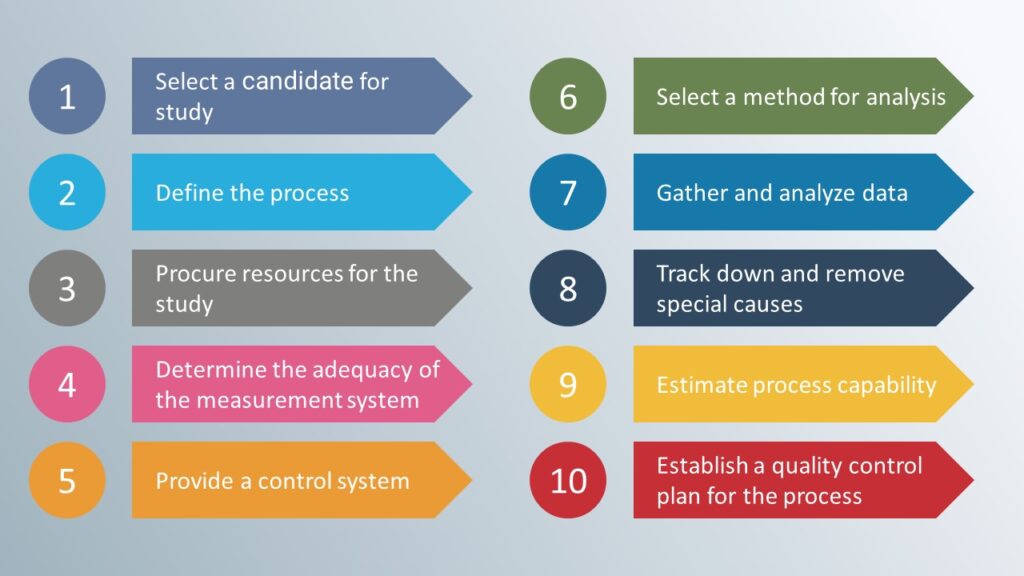

A Ten-Step Plan for Statistical Process Control Studies

Statistical Process Control (SPC) is the latest name used to describe the use of statistical methods to control process variation. Since the time of Shewhart, it has been known that we can improve process performance by using valid statistical methods to analyze data gathered from the process. In the U.S., the techniques were used during WWII on a broad scale. The postwar period saw SPC atrophy here, but our competitors in Japan kept the techniques alive and used them to capture markets from U.S. manufacturers. A 1979 NBC white paper, “If Japan Can, Why Can’t We?” caught the attention of key executives in the automobile industry (and others) and SPC was reborn in the U.S.

The heart of applied SPC is the process capability study. A ten-step plan can help you select a candidate for study, conduct the study, interpret the results, and hold the gains made during the study. These steps represent a guide that I have found useful in conducting dozens of such studies over the years.

1. Select a candidate for study

This step should be institutionalized. A goal of any organization should be ongoing process improvement. However, because a company has only a limited resource base and can’t solve all problems simultaneously, it must set priorities for its efforts. There are several tools available to assist in this effort: Pareto analysis and cause-and-effect diagrams are among the most popular.

It often happens that existing data do not provide the information needed to select an SPC candidate. One reason is that the emphasis of many quality programs has been the detection of discrepant product rather than the control of processes to prevent the discrepancies. Thus, you may find that the “pain signals”—to borrow a term from Joseph M. Juran—have been killed. For example, I know of one instance where a soldering operation was considered satisfactory even though every single circuit board required touchup. The company had long since decided to accept the nonconformances as inevitable and had written touchup into the manufacturing plan as a normal production operation. Painless. Invisible. Expensive.

In cases like that one, you may need to dig deep to find evidence of the need for an SPC study. Try to find statistical data that have persuasive power. This data can be quite simple.

- In the soldering operation described previously, 40% of the hours allocated for production of a typical circuit board were for various inspection and touchup operations.

- An operation had short, but frequent, stoppages while the operator “tweaked” a machine setting. The problem was due to misalignment of electronic components on the reels used to feed the automatic insertion equipment. This situation had always existed, and no one felt the problem was serious. By using work sampling, we were able to show that the “short” stoppages were so frequent that the equipment was being utilized only 45% of the time.

- In a circuit board assembly operation, 40% of the factory space was dedicated to troubleshooting and repair.

2. Define the process

It is easy to slip into the trap of trying to solve the wrong problem. There is a strong tendency to point fingers in the early stages of an SPC study. Once the SPC study candidate has been selected, define the scope of the study. A process is a unique combination of machines, tools, methods, materials, and personnel engaged in production. Each element of the process should be identified at this stage.

Be aware that this is not a trivial exercise. The input of a large number of people may be required. There may be conflicting opinions on just what the process is: these differences must be resolved at this stage if possible. The work done at this stage will pay off many times over when the study is actually performed. The results should be documented, and a flow chart of the process constructed.

3. Procure resources for the study

Most SPC studies disrupt production and require significant expenditures of material and human resources. This means that management backing is essential if any true progress is to be made. The evaluation done in Step 1 and the process definition agreed to in Step 2 should give you enough information to convince management to support your effort.

Develop a plan for the study at this stage. The plan includes a description of the overall approach to be used in the study. Questions that must be answered include these: Will the process be allowed to run “unperturbed” for a while? Who will take the data? What forms will be used? How long will the study take? How will management be kept up to date on results? Which characteristics will be monitored?

4. Determine the adequacy of the measurement system

A measurement system must be accurate and repeatable enough to measure process variation. It should also be consistent. These features should be evaluated statistically, not on the basis of intuition or opinion.

5. Provide a control system

Identify as many variables as possible in advance. A variable here is anything you suspect may be an assignable cause of variation. These include different vendors, tools, machine settings, fixtures, operators, machines, and so on. Once these sources of variation have been identified, be sure that the system provides a means for identifying the units in a manner that allows you to determine which variables have changed. If possible, control the changes in the variables so that you can investigate the effect of the change.

Since many variables change over time—including some you probably do not have on your list—the data-gathering system should identify the sequence in which the product is made. Identify parts actually measured as part of the study in case further evaluation is necessary. Everyone involved in the collection of data should be trained in the methods used to gather and record the data. Allow the observations and notes to be recorded in a convenient manner: every SPC study is an effort to learn more about the process, and it is often convenient to write notes and observations right on the control chart.

The control plan is not an effort to eliminate variation artificially in the independent variables. If an input variable is likely to vary in the normal course of events, then it should be allowed to vary during the study, with changes duly noted. Deliberate changes may be induced (e.g., tool changes, material changes, break and lunch shutdowns, shift changes, different inspectors). The advantage of deliberate change is that you know what just changed; in other cases, you are often forced to guess. The changes should be noted on the charts; even if they had no effect, you’ve still learned something.

6. Select a method for analysis

This is normally a control chart of some kind. The type of control chart will depend on the characteristic selected.

The standard control chart is not always the best method of analysis, though its popularity for the past 50-plus years suggests that it is a good place to start. Many other methods exist if your situation doesn’t lend itself to control charts. I prefer the graphical methods and find it easier to explain them to other members of the SPC team. When the runs are very small and short in duration, multi-vari charts are very useful. The SPAN plan method of process capability analysis is a “canned” approach useful for those who have little background in statistical analysis but are faced with a complex part or process.

The simpler techniques often yield the most information. For example, when using blueprints or manufacturing plans, you may wish to record your results directly on copies of these documents. By using this approach, you may see patterns that would be very difficult to find otherwise. This also applies to variables or attributes data.

7. Gather and analyze data

The objective here is to locate patterns that are nonrandom and need further investigation.

8. Track down and remove special causes

Special causes of variation, which Shewhart refers to as assignable causes, are those that produce an effect too large to be due to mere chance. A special cause is, by definition, not inherent in the system. Special causes have been referred to as “ghosts” because they often come and go in a process without being identified. However, the effects of the special causes are easily identified on control charts by applying statistical tests.

Many people believe that all special causes of variation can be controlled by operators. This is not true. A special cause may have been created by the engineer who did a poor job of defining the process—for example, by including more than one part number on the same control chart. Remember, all that an out-of-statistical-control point tells you is that something has changed; the cause of the change cannot be known without investigation.

9. Estimate process capability

The process capability cannot be estimated until a stable process has been achieved. Stable means that all the observed variation over a considerable period of time is random in nature. You’ve exorcised the “ghosts.” It is important to remember that process capability is an effort to relate management’s goals to the actual process performance. When we discuss capability, we are defining what a process will be expected to do over the long run. We can say this using measurement units, or percent nonconforming, or some other performance criterion, but the significance of the process capability can only be assessed in light of management’s objectives for the process.

The techniques used to estimate process capability vary. The use of probability paper is quite common, as is the simple computation of “3σ limits.” When using X-bar charts as the process control device, you must remember that process capability refers to the individual units, not the sample averages. Also, be aware that, while sample averages are usually normally distributed, the same does not apply to the distribution of the individual values. You may find it necessary to study the underlying distribution of the data, which may require some expert statistical help. On the other hand, you may get lucky. If your performance measure is yield, it may be just the figure your management is interested in, and you can estimate the process capability as the average yield.

One bit of advice: use common sense in evaluating your capability estimate. Since the process has operated for a considerable time in statistical control, you can obtain a rough estimate of the capability by counting the pieces out of specification. If the count is at odds with the results of your more sophisticated analysis, beware.

Process capability is usually measured in terms of the units used in the SPC study. This may be inches, nonconformances, percent nonconforming, or some other unit. The objective is normally to compare the expected process output to an engineering specification or management goal. Management is usually interested in the process yield, cost, customer complaints, excess inventory required for buffer stock, effect on downstream operations, or other relevant business measures. Once the process is in statistical control, it is usually possible to estimate the desired criteria—many for the first time. This is the true payoff of SPC—facts on which to base management decisions. Until statistical control is achieved, many management decisions are pure guesswork.

10. Establish a quality control plan for the process

Plan selected depends on the outcome of the SPC study, but it will usually contain one or more of the following:

- Surveillance, perhaps using control charts, of important process variables.Inspection of control dimensions.

- The inspection data are usually subject to statistical control to detect problems before unacceptable product is made.

- Sorting inspection if process performance does not provide the desired level of quality.

- Process improvement program to assure that progress continues to be made. Three process improvement programs that are enjoying some measure of popularity are zero defects, quality circles, and evolutionary operations.