Your cart is currently empty!

-

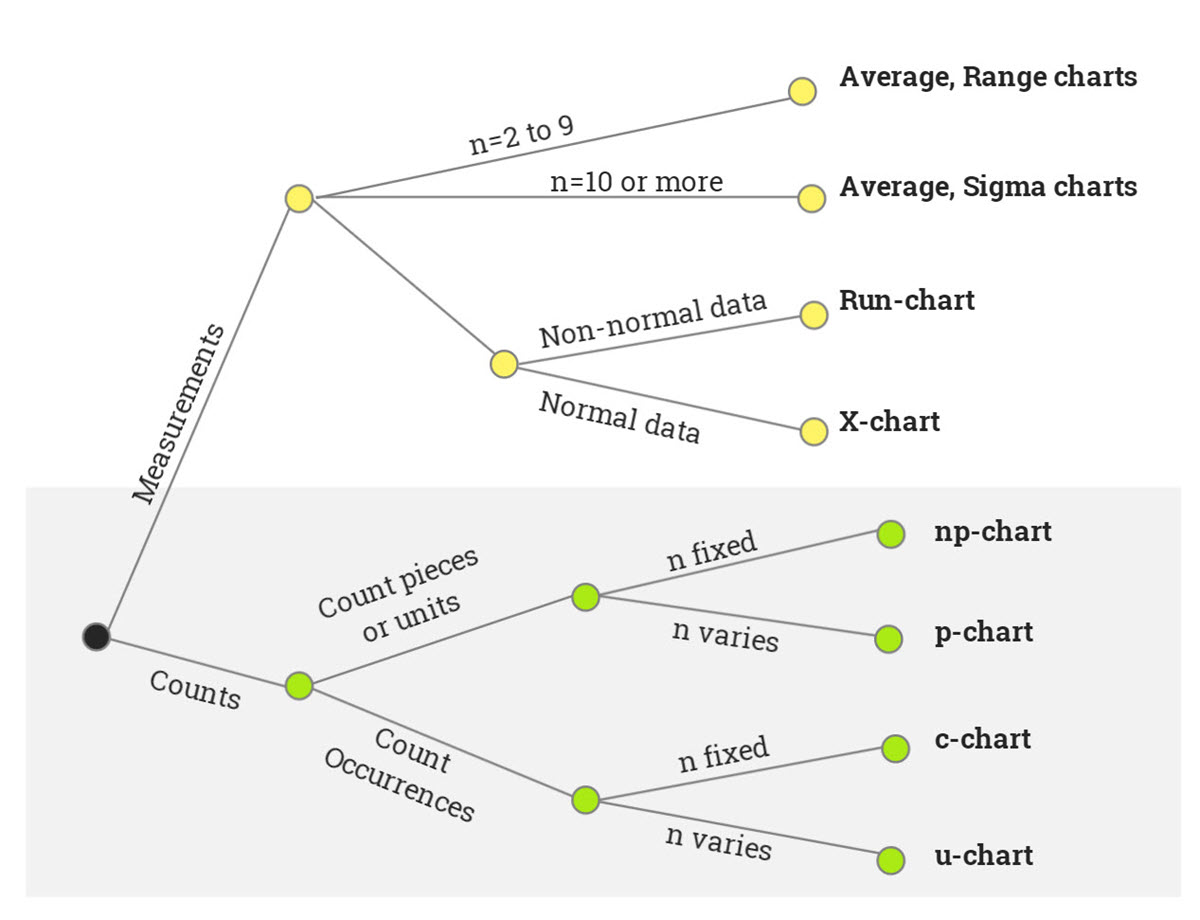

When in Doubt, Get the X-Chart Out!

Phil looked at the data Joan had just handed him. Joan was a recent graduate of an SPC seminar the company had sponsored for administrative personnel and, since Phil had been the Quality Engineer who taught the classes, it was only natural that she would seek his help. She was trying her best to follow…

-

Recognizing a Six Sigma Project Opportunity

Lean Six Sigma projects must help the organization achieve its goals. To accomplish this you must take action that guarantees that your project activities are directly linked to the goals specified by your leaders. Example of a CEO’s Vision Six Sigma begins with the vision of the senior leader and his or her team. The…

-

Becoming a Lean Organization in Eight Steps

Becoming Lean: A Tactical Perspective At the strategic level, becoming Lean involves a culture change. An organization ready for Six Sigma is also ready for Lean. However, there are some differences in the deployment of the Lean model. Becoming Lean requires an organization where continuously improving is part of the culture. Here are some guidelines…

-

The 8 Types of Waste in Lean

What is Lean? Lean’s origins date back to the post-WW II era in Japan. It was developed by Taiichi Ohno, a Toyota production executive, in response to a number of problems that plagued Japanese industry. In fact, what we now refer to as “Lean” is based on the Toyota Production System. The main problem facing…

-

Lean Six Sigma Project for Nonprofit Organization

In this webinar, presented by Lean Six Sigma Black Belt Richard Petty, you will be shown an example of the benefits derived through the use of DMAIC within a Non-Profit Organization (People in Need Ministries) where the focus is not so much on metrics, as it is on people. Richard used this as his Pyzdek…

-

Misdirected Submissions to Billing Administration

Project Title: Misdirected Submissions to Billing Administration Define Project sponsor: Stephanie Project Green Belt: Steve The issue here was fairly straightforward: agents were transferring calls to Billing Administration that should not have been transferred. Although Billing Admin does handle a wide variety of billing and account issues, many of these can be handled more effectively…

-

Case Study – Attaching Direct Deposit to DIY Payroll

Project Title: Attaching Direct Deposit to DIY Payroll Define Project sponsor: Stephanie Project Green Belt: Mike Mike examined how we could increase the number of Direct Deposit customers in conjunction with their DIY service. Although the fee [company] receives for each Direct Deposit payroll transaction is a small amount, when multiplied by the number of…

-

Case Study – Recovery of Mislabeled One-Time Support Calls

Project Title: Recovery of Mislabeled One-Time Support Calls Define Project sponsor: Bruce Project Green Belt: TC A group of Service Employees who were hired during the high volume early [software product] season to handle simple refund issues and other simple service questions were getting misrouted customer calls. The Integrated Voice Response (IVR) was supposed to…

-

Case Study – Increase Order Status IVR Resolution Rate

Project Title: Increase Order Status IVR Resolution Rate Define Project sponsor: Kemper Project Green Belt: Jeanette Jeanette was tasked to look at a low resolution rate for a particular type of call – a customer calling the automated order line to check on the status of their order. Approximately 46,000 customer calls passed through the…

-

Case Study – Improve Information Sharing with Call Center Planning

Project Title: Improve Information Sharing with Call Center Planning Define Project sponsor: Jeremy Project Green Belt: Michelle Any time that a product or service is launched, DST, STS, Marketing and other groups must coordinate their efforts to succeed. With the existing lack of coordination and multiple communication channels, documents were “flying all over the place”…