-

The Truth About DOE, Part 2

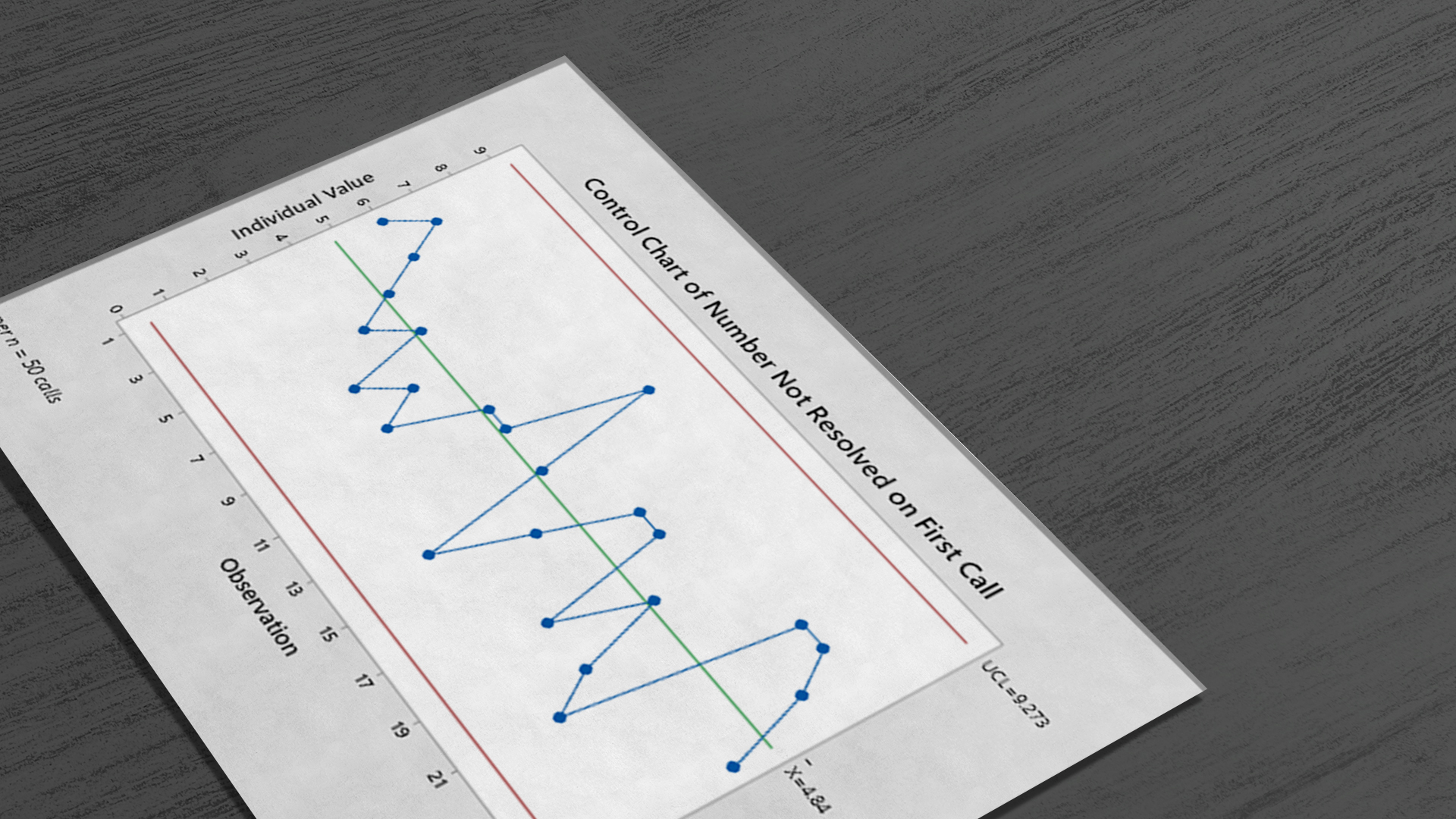

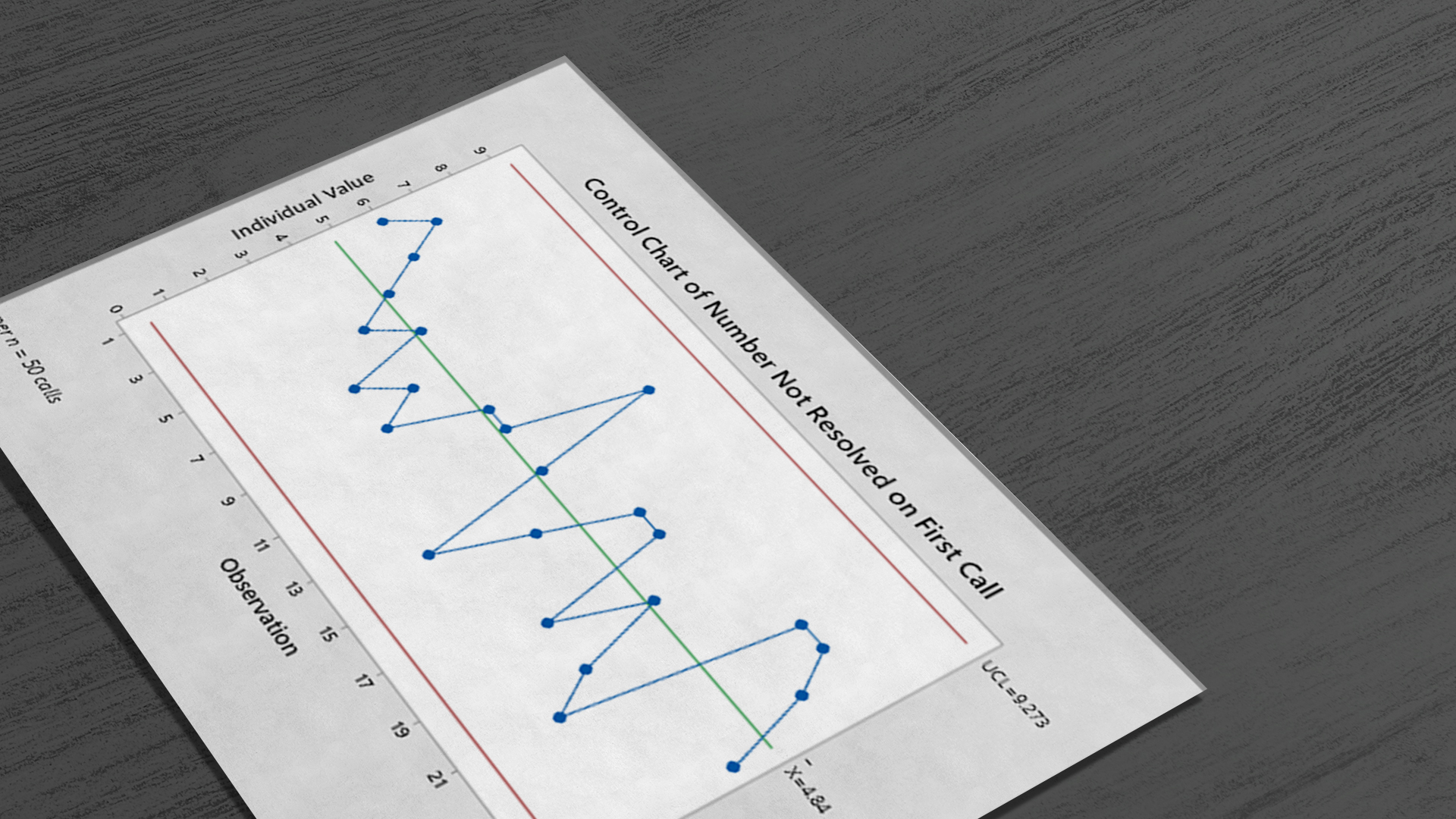

Part 1 of this series set the stage for a critical look at the way we prepare to run a designed experiment. It also demonstrated the use of control charts to improve the probability of DOE success. Part 2, is a look at the use of Fitted Line Plots to help us toward the same…

-

The Truth About DOE, Part 1

Design of experiments (DOE) and robust design of products are key parts of the Six Sigma process. To stay competitive, we need to offer great products to customers and we need to find and validate the optimum process settings to actually make the products. In short, we need a statistical model of our process. However,…

-

Process Capability-Let’s Skip the Jargon

To many quality engineers and managers, process capability is a jumbled confusion of ideas expressed in jargon that only the anointed can understand. Let’s skip the jargon. Imagine the following scene. The boss rushes into the quality director’s office. He’s obviously distraught. (Boss enters, walking quickly from stage right.) Boss: “Jane, we’ve got a serious…

-

Fight Boredom With an Improvement Project

Have you ever had a boring job? One where you did the same things day-after-day for months or years on end? Well then, shame on you! There is a saying that the biggest room of all is the room for improvement. No matter what your job is, there is room to do it better. Figuring…

-

Experiments With a Sample of n=Me

In statistics a great deal of attention is paid to proper sample size, and rightly so. There are many tools and techniques devoted to solving the problem of how many to include in your sample. Computers have made it easy to perform the calculations necessary to determine sample size. In science there is a widely…

-

Statistics—The Good, the Bad and the Ugly

The quality and process improvement professions tend to rely heavily on statistical information. The very science of quality control can be said to have begun with Walter A. Shewhart’s development of the control chart and discovery of the concepts of special cause and common cause variation. And where would Six Sigma be without statistics? But…

-

Can SPC Save the World?

As we navigate through these uncertain times, it becomes apparent that our understanding and response to the situation could greatly benefit from improved data quality and analysis. The complexity of the current health situation calls for a time-tested tool from the industrial world: Statistical Process Control (SPC). For over a century, SPC has been guiding…

-

Let’s Return to Simple

I recently re-read my original book An SPC Primer originally published in 1978. It brought back my early days in process excellence. At the time I was the only quality control person in a factory that covered an area of 1 mile plus. I was working the graveyard shift and my task was twofold. As…

-

Does Normality Really Matter in ANOVA?

I had a spirited discussion with a statistician earlier today on the subject of the normality assumption for one-way ANOVA. In the end, we both agreed that normality of the response variable doesn’t usually matter much, despite the fact that it is an assumption that is usually tested. The truth is, it takes a pretty…

-

Pyzdek Institute Black Belt’s Book Clarifies Confusing Concepts in Statistics

I’ve taught the Six Sigma process quality methods to many students over the years. Invariably, it’s the statistics that confuses people the most. There has been a real need for a book that clears up this confusion. Now, a graduate of the Pyzdek Institute Black Belt program has done something about that. Andrew A. Jawlik…