Leading an entire organization is a daunting challenge. One must keep everyone happy. A delicate balancing act, to say the least. We Six Sigma practitioners are often quick to criticize leaders for not properly supporting our efforts. But what if you were asked by a committed leader for advice on how to actually use Six Sigma to help them lead the enterprise? Do we have anything to offer?

The answer, I believe, is yes. When I studied management in college I was struck by the fact that it focused largely on control systems. There were systems to control expenditures, quality, personnel, work flow and everything else in the organization. But are businesses all about control? Six Sigma says no. Businesses are about processes that deliver value to stakeholders. And most leaders, who are trained as managers, are not familiar with this view of their organization and don’t know how to use it to their advantage. We can enlighten them.

What Do Leaders Need To Do To Create Excellent Processes?

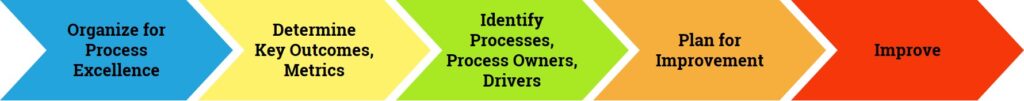

Phil Crosby once said that quality professionals spend too much time complaining about lack of leadership support. Most CEOs, Crosby said, have no clue what we mean when we say we want their support. Leaders are doers. We must tell them what they need to do. While the leadership process is complex, it can still be described in simple terms, as shown in Figure 1.

Organize for Process Excellence

The leader can’t achieve process excellence on his own. He needs to create a process excellence leadership team, or PELT. The PELT will be responsible for helping the leader achieve his process goals. They must receive training in their new responsibilities and they must meet on a regular basis to prepare plans and to review progress.

Determine Key Outcomes and Metrics

The process of identifying key outcomes of the organization begins by identifying the goals for each stakeholder and the organization’s strategies for achieving these goals. Strategies are meaningless abstractions until the PELT identifies the metrics that operationalize the strategies. Typically, there are too many metrics for a leader to follow closely. While all metrics are important, the PELT must identify the critical few metrics that will differentiate their organization from its competitors. These “differentiators” will be monitored over time on dashboards that are part of a balanced scorecard.

Identify Processes, Process Owners, Drivers

The most important processes in the organization are those that serve customers directly. These are the organization’s core processes. Each core process, and there will be very few, must be defined. An owner must be identified for each core process and given the authority to design and measure the process. Ideally, the process owner will have a voice in assessing the performance of functional leaders who contribute to her process.

In addition to core processes there are enabling functions. These are functions that do not serve customers directly, but they provide resources to the core processes. Examples of enabling functions are IT, quality assurance and human resources.

Core processes must be linked to the balanced scorecard and dashboard. They must each be mapped to an actionable level. This means that the activities of the core process will be defined in sufficient detail to allow the measurement of their impact on the effectiveness of the organization’s strategies. At this level we will be able to determine the critical to quality drivers in the process, also known as CTQs.

Plan for Improvement

Once the process owner has identified the CTQs for her process, she can work with the functional managers and her own PELT to generate plans for improving the CTQs. The plans must be validated by mapping them back to dashboard metrics. The process owner must work to get shared vision on her plans among those who will be involved in executing them. Not all improvement will take place as a result of Six Sigma projects or activities. The PELT must identify the best way to achieve the improvement goals.

Improve

If the path to improvement involves projects, the process owner or functional manager’s PELT must identify the projects, prioritize them, and assign sponsors to them. Project identification involves creating problem statements, business cases, and draft charters. In some cases the PELTs will work with the sponsors to identify team leaders. Project kickoff meetings that include a member of the PELT or the process owner will give the team a sense of the importance of their project to the organization, and it will help them determine the line of sight linkage between their project’s goals and the goals of the larger organization.

Since success will depend on the effectiveness of the project teams, the top level leadership will want to monitor the project schedules and the success of the project teams. This will take place during regularly scheduled dashboard reviews. Also, because the business environment is dynamic and constantly changing, leadership must meet frequently to review their strategies to assure that they remain relevant.

Summary

Leadership is simple, but it is anything but easy. Most leaders wake up each day and hope that the people in their organization will do great things to move the organization forward. The Six Sigma leadership process makes this a lot more likely.

Leave a Reply