Your cart is currently empty!

The Visual Safety FMEA

A few weeks ago, we pondered the use of a simplified, visual approach to FMEA as an alternative to classic Failure Mode & Effects Analysis (FMEA). The goal of Visual FMEA is to draw more people and their skill sets into the conversation about risk identification and remediation. While the visual approach to FMEA isn’t suitable for all applications, it is an excellent method for improving safety. And, of course, nothing is more important to an organization than the safety of employees, contractors, visiting customers and other stakeholders.

To recap, an FMEA answers the following 3 questions.

- What has gone wrong in the past?

- What could go wrong now or in the future?

- What can we do about it?

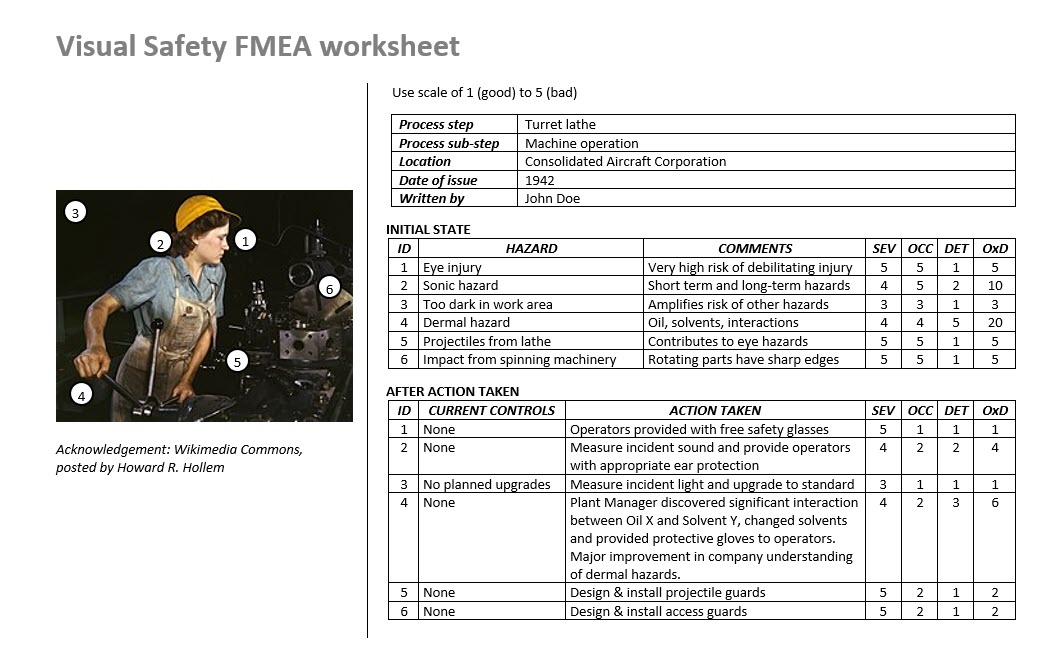

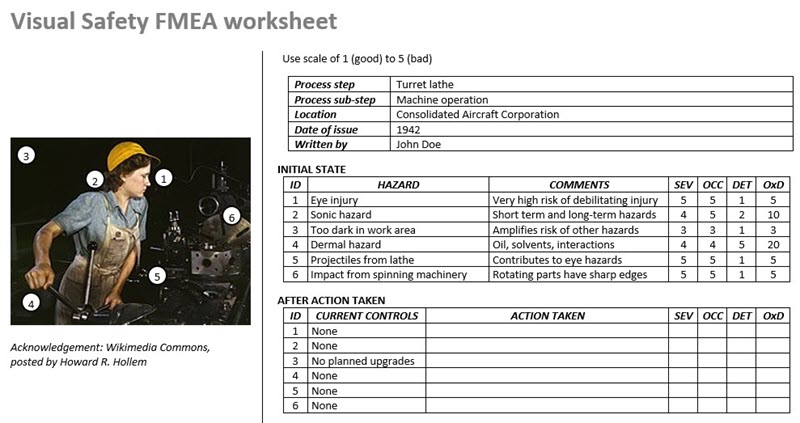

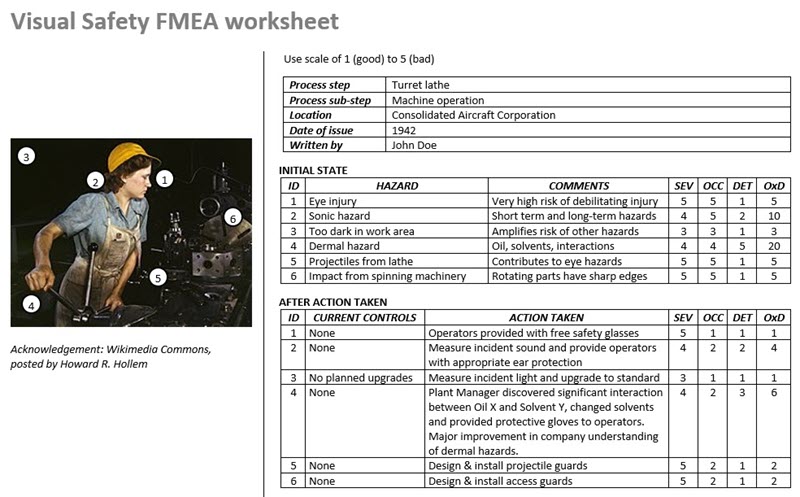

Visual Safety FMEA example

In practice, a group of 2-3 people visits a work area, talks to operators about their safety concerns and an appointed FMEA Scribe assimilates the insight gained into a simple form and support photograph. This exercise answers the first two questions.

Potential users should note that videos also work well and that safety hazards can be indicated by recording the time at which the hazard occurs in a video or by annotating the hazard with video editing software. Either way, hazard visualization has significant advantages over notes written in tiny fonts in a large spreadsheet.

Below is an example of the document after evaluation, but prior to remedial action. Unlike the three-way RPN value (Severity x Likelihood of Occurrence x Detectability), the calculated rating for the visual method is simply the Likelihood of Occurrence times Detectability (OxD). The reason: the safety Severity Rating doesn’t change, it is what it is.

The team then decides, with additional operator input, on a course of action and summarizes the results in a new set of scores as shown below. This exercise answers the third question (What can we do about it?) and provides a framework for immediate action. In the example, the team decided to clarify chemical interactions, upgrade lighting, build or issue protective devices and take other steps to improve operator safety.

Here’s the takeaway. The focus of a Visual Safety FMEA is on personnel and their work area, not on a spreadsheet. This simple, visual approach draws more people’s expertise into safety improvement efforts. Now who can argue with that?

Next time: Convert opinion to continuous data for fifteen bucks

Leave a Reply