Your cart is currently empty!

What Are SIPOC Maps and How Do You Use Them?

Kirby had been a service agent at the sales contact center for a long time. And he was a good one, one of the best. But his promotion to supervisor for a small group of agents was a new job to him and he wanted his team to do their job better. There were many reasons for this. It would help Kirby deliver on his boss’s goal of improving the percentage of customers who would recommend the company to others. It would make the experience of Kirby’s employees more satisfying. And, frankly, it would make Kirby’s job more pleasant as well. Towards that end Kirby had called a staff meeting to get his team to work on performance improvement.

Just one problem: what exactly did the team do?

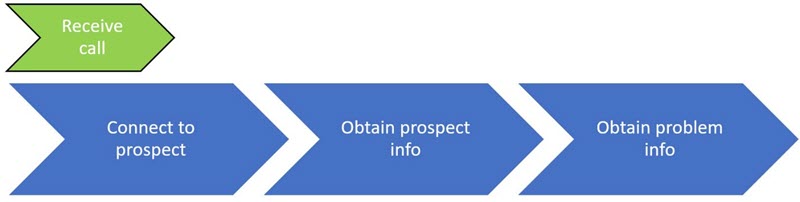

Kirby had begun the meeting by asking for ideas for improvement, but the meeting quickly bogged down in a morass of detail that seemed to go nowhere. Kirby decided to try getting them on track by getting the team to agree on what the group did in an ideal scenario. The team eventually arrived at a consensus for one of their processes, making a sale by phone:

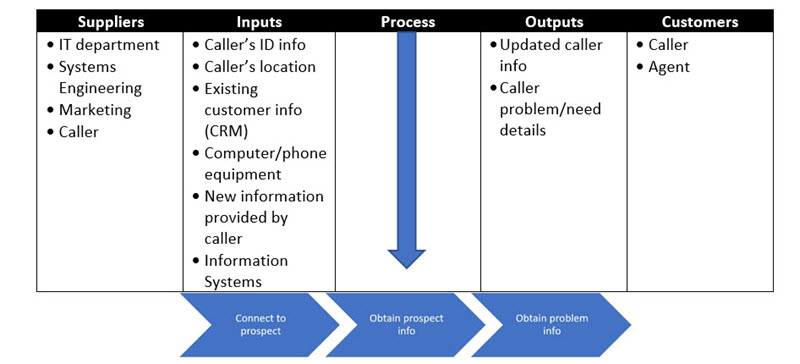

When the team tried to use this process map (called an L-map) to identify an improvement, it quickly became clear that it was still too big a task. Kirby decided to start at the beginning: receive call. The team repeated the process they used to create the chart in Figure 1 to create Figure 2-Receive Call Process.

The team discussed the process and decided that the “connect to prospect” step would be a good place to start improvement. Kirby, a trained Lean Six Sigma Green Belt, decided to introduce the team to a tool he’d found to be extremely valuable: a SIPOC diagram.

What are SIPOC diagrams?

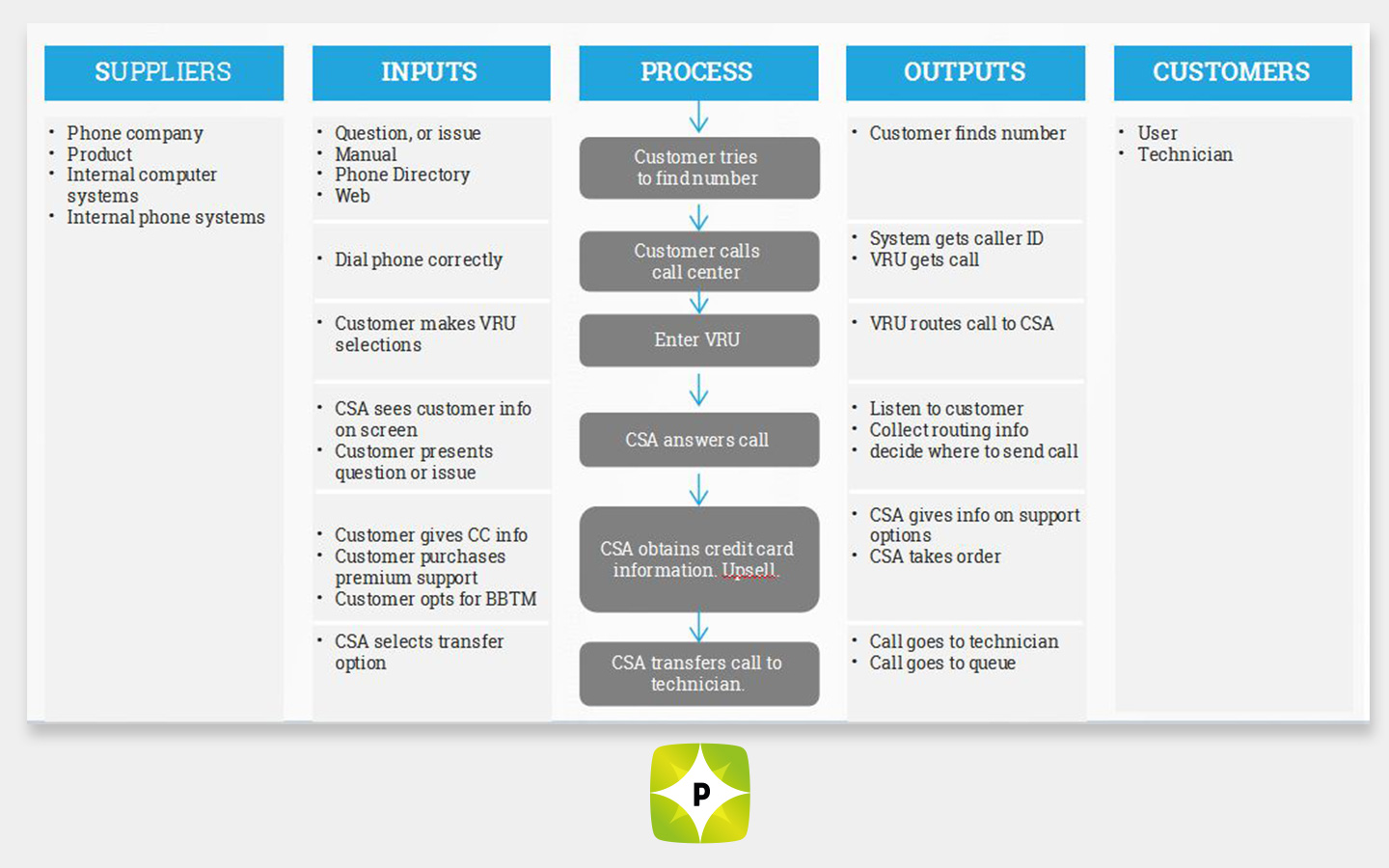

SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. SIPOC maps are part table, and part diagram. The SIPOC map shows the whole process from the suppliers to the customers. SIPOC maps are important six sigma tools because they help the improvement team identify the key parts of a process. Clear starting and stopping points help the team understand the scope of the project, including what is in the scope and what is not. Here’s the first draft of the SIPOC diagram for the receive call process.

How are SIPOCs used?

This draft SIPOC provided a starting point for the team and it helped them to see some of the details of the process of receiving a call and engaging the caller. This knowledge provides the context for improving one important part of the process of obtaining a sale. As the team moves forward with the project they will use the SIPOC to focus on specific elements that could be improved. Inputs are usually improved by either simplifying the process to eliminate the need for a particular input, or by working with the suppliers of the inputs to redesign or fix them. Outputs are improved by communicating with customers to find problems and to identify ways to prevent the problems or by helping customers identify ways to mitigate problem effects. Processes are improved by changing the process to make it more consistent, more robust to changes in the inputs, and more efficient.

Contact Pyzdek Institute today to learn more about SIPOC or other six sigma tools.

Reproduction allowed if no changes are made to content and you link to this article.

Leave a Reply