Packaging World reports that a recent survey highlighted a significant gap among packagers regarding the importance of quality and their strength in the quality area. The article, which appears in the February 2011 issue of Packaging World Magazine, found that in most areas there was plenty of room for improvement. However, two areas stood out from the rest in terms of importance: packaging engineering and quality assurance. Both of these areas showed that strength in these areas fell well below their importance scores.

Methodology

The survey methodology was simple and straightforward. Each survey recipient was asked:

- What is the importance to your company of key packaging department capabilities?

- And for each capability, how would you rate your company’s strength?

The survey covered such key capabilities as packaging engineering, material development, and program management. Respondents ranked functions on a one-to-five scale from “not important” to “very important.”

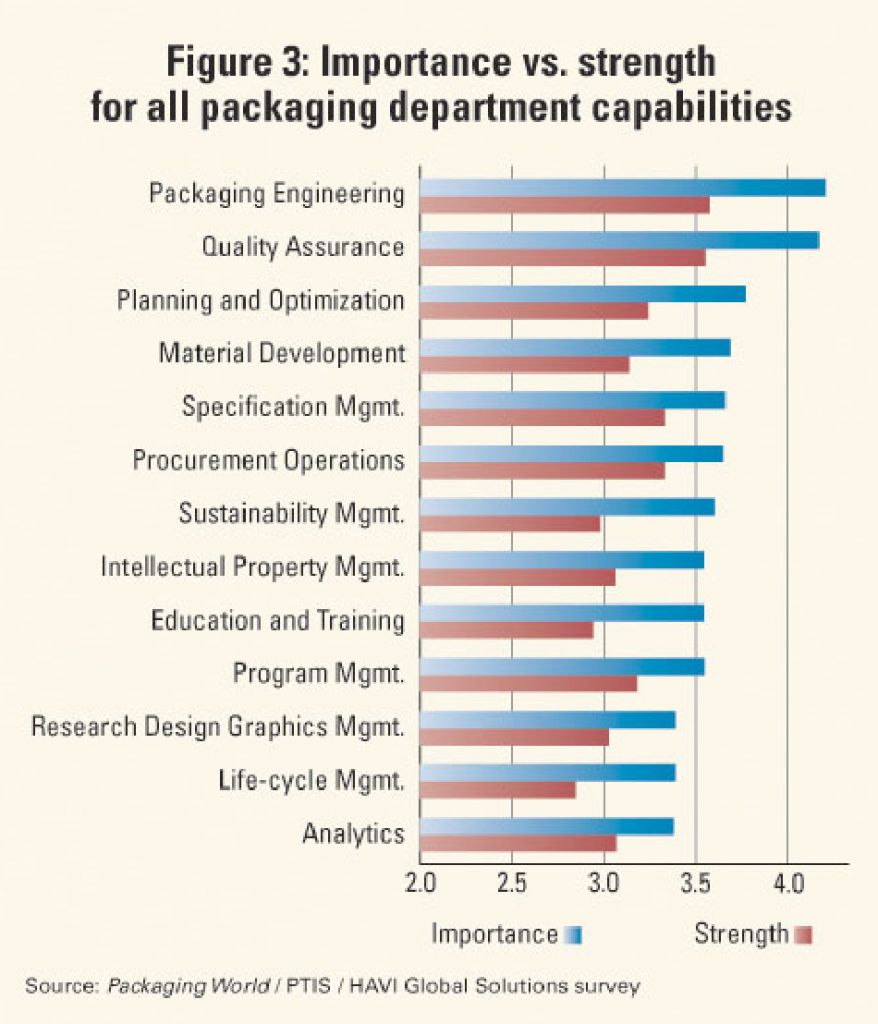

Then, respondents made a second ranking, this time rating whether a function was “weak to strong” in the respondent’s packaging department, also on a one-to-five scale. Leading the list of important packaging functions was packaging engineering and quality assurance (Figure 3). Respondents ranked packaging engineering at 4.2 and quality assurance at 4.17 on the survey’s one-to-five scale—clearly standing above other functions in importance.

Quality Gap Significant

The quality assurance function saw a 0.6-point gap between importance and strength, the same gap as with packaging engineering. But the reason for the gap is related more to technical issues. “It probably reflects technical training more than business issues,” says Packaging & Technology Integrated Solutions, LLC’s Wagner. He notes that the way quality assurance is handled today compounds problems seen with packaging recalls.

“In my early career, we received frequent training on statistical process control,” says Wagner. “Some packaging professionals today receive training and certification in Lean Manufacturing and Six Sigma quality programs. However, it is not emphasized as a standard part of development and training. At the same time, quality assurance groups have been cut over the last 20 years, with more emphasis applied to the suppliers, with expectations that they will assure quality-delivering COAs and COCs with their products. Unfortunately, quality issues, including packaging-related product recalls, have become ‘normal.’”

HAVI’s Biddie offers this insight, “We suspect that challenges related to specification management may be captured as a gap under quality assurance. Companies may believe they are doing spec management sufficiently well, but the problems are captured during the quality assurance process. Companies need to build the business process and integrate quality assurance into their business model.”

A number of survey respondents from overseas said global sourcing may also influence the gap between importance and strength in quality assurance. Survey respondents reflected packaging’s global nature today with about one in five from organizations located outside the United States. U.S.-based multinationals also added to the global scope of respondents.

India and Latin America were dominant locations of non-U.S. companies answering the survey. This is consistent with forecasts that see India and Latin America as emerging economies poised for major growth in the next five years. “We believe that India and Latin America are two strong emerging markets; they have developed the infrastructure and are searching for technical knowledge,” notes HAVI’s Biddie.

One of the overseas respondents to the survey puts the overseas quality assurance issue in this light: “Quality cost is too high. In our country, the majority wants cheap products.”

Improvement

Responses to the survey raise this question: If the importance of a capability is perceived as high but the company’s strength in that capability is recognized as low, what’s the best way to close the gap between perceived importance and recognized strength? The answer, according to the analysis of those who authored the survey, is to build a set of integrated capabilities that packaging pros can use to meet greater corporate challenges. These integrated capabilities could be developed by making use of the Lean, Six Sigma, and Quality professions’ bodies of knowledge.

Leave a Reply