Your cart is currently empty!

Six Sigma, Lean, and Lean Six Sigma

Which process improvement approach is right for you and your needs?

People sometimes ask me to explain the difference between lean production and six sigma. The question is usually phrased something like, “Should I use six sigma or lean production methods to improve my operations?” Before I tell you my answer, let me provide a brief background on these different approaches to process improvement.

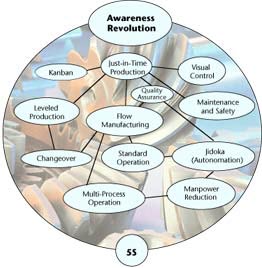

Lean production is based on the Toyota Production System and usually includes the elements shown in Figure 1. When properly implemented, a lean production system can dramatically improve productivity (by as much as 95 percent when compared with traditional batch-and-queue production systems).

Lean production dates back to the post-World War II era in Japan. It was developed by Taiichi Ohno, a Toyota production executive, in response to a number of problems that plagued Japanese industry. The main problem was that of high-variety production, required to serve the domestic Japanese market. Mass-production techniques, which were developed by Henry Ford to economically produce long runs of identical products, were ill-suited to Toyota’s situation. The lean approach (the term “lean” was coined in the early 1990s by MIT researchers) systematically minimizes waste–called muda–in the value stream. Muda includes all types of defective work, not just defective products. Wasted time, motion and materials are also muda.

OK, so how does this relate to six sigma? To make a valid comparison, we need a new definition of quality itself. By defining quality in terms of value rather than in terms of defects, we can see that six sigma quality involves a search for ways to reduce muda . I propose the following definition for six sigma:

A general approach to reducing muda in any environment

A collection of simple and sophisticated methods for analyzing complex cause-and-effect relationships

A means of discovering opportunities for improvement

The lean approach offers a set of solutions to muda in a high-variety production environment. Six sigma applies to the problems addressed by lean but also seeks to solve other problems common to production. However, because both six sigma and lean address the problem of muda, there is a great deal of overlap. The approaches should be viewed as complements to one another. Some examples of this synergism are shown in Table 1.

| Lean | Six Sigma Contribution |

|---|---|

| Establish a methodology for improvement | Policy deployment methodology |

| Focus on customer value stream | Customer requirements measurement, cross-functional management |

| Use a project-based implementation | Project management skills |

| Understand current conditions | Knowledge Discovery |

| Collect product & production data | Data collection and analysis tools |

| Document current layout and flow | Process mapping and flowcharting |

| Time the process | Data collection tools and techniques, SPC |

| Calculate process capacity and Takt time | Data collection tools and techniques, SPC |

| Create standard work combination sheets | Process control planning |

| Evaluate the options | Cause-and-effect, FMEA |

| Plan new layouts | Team skills, project management |

| Test to confirm improvement | Statistical methods for valid comparison, SPC |

| Reduce cycle times, product defects, changeover time, equipment failures, etc. | Seven management tools, seven quality control tools, design of experiments |

If you’re facing a situation where lean solutions can be used (e.g., high-variety production), you shouldn’t hesitate to implement lean: It offers proven solutions to known problems. Six sigma methods will help you with lean, and they will help you continue to improve when it’s time to move into administrative and other nonproduction areas.

Lean Six Sigma

A quick review of the above should make it clear that there is a natural affinity between Lean and Six Sigma. This has been incorporated into a single approach to business improvement: Lean Six Sigma. Lean Six Sigma takes parts of Lean and parts of Six Sigma and puts them together in a single, integrated approach to achieving process excellence. Organizations can move from Lean or Six Sigma to Lean Six Sigma, or they can simply introduce Lean Six Sigma from the outset. If an organization is just starting the journey to excellence, I recommend the following:

- Begin with Lean. Identify value streams for the most important product families and move these as closely as practical to one piece flow based on pull systems.

- Examine the improved value streams to determine where obstacles exist to moving closer to one piece flow. These obstacles will generally be caused by excessive setup or changeover times, information flow issues, excessive variation, and other forms of muda.

- Decide how best to deal with each obstacle on an issue-by-issue basis. Some can be remedied by “just do” projects, others by Kaizen events, others by routine continuous improvement activities, and still others by applying Lean Six Sigma.

Of course, for most organizations conducting these improvement activities will require a complete transformation in the culture of the organization. But that’s the topic for another post!

Leave a Reply