We are all fortunate to have the accumulated knowledge of manufacturing industry titans readily available to help us improve processes and reduce costs. In the Lean context, Taiichi Ohno and Shigeo Shingo stand out. They taught us much about the process improvement mindset, visual control systems and the like. Both indicated the need to relentlessly identify process waste and do something about it. We started with the list of 7 Deadly Wastes and eventually added safety and wasted talent as Deadly Wastes #8 and #9.

In the spirit of continuous improvement, The Pyzdek Institute proposes taking that list even further.

The Original List

| 1) Transport | 6) Over-production |

| 2) Inventory | 7) Defects |

| 3) Motion | 8) Safety |

| 4) Waiting | 9) Under-utilized talent |

| 5) Over-processing |

Our proposal

We propose adding other forms of waste to this list and we’ll cover the particulars of the list expansion in future blogs. One example is the waste of bad data.

Meanwhile, to benefit Lean Thinkers everywhere, The Pyzdek Institute has accumulated real-world examples of The Nine Deadly Wastes to make available to Lean Thinkers everywhere. To that end, please post in the comments section below any examples that you’ve encountered. We’ll add them and post downloadable documents to the Pyzdek Institute website. Additionally, please highlight examples where one form of waste causes another (see last bullet point below).

A Brief Overview

Transport waste is defined as the physical movement of materials that does not add value to the product. Batch & queue process, like the one shown in the photo, are highly susceptible to Transport waste.

Root causes of Transport waste include poor equipment layout, indirect product workflow, the presence of forklifts and tooling used over large areas of a facility. To identify Transport waste, observe workflow from a panoramic viewpoint, discuss solutions with Process Owners and take action.

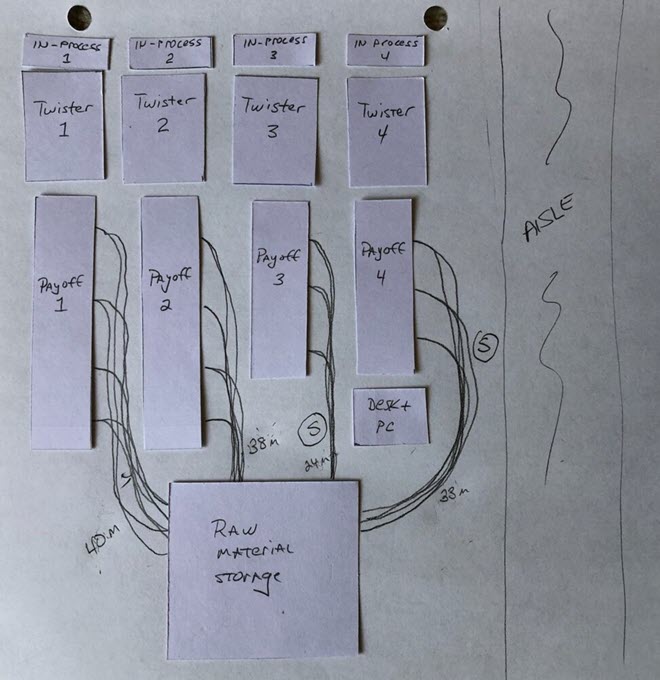

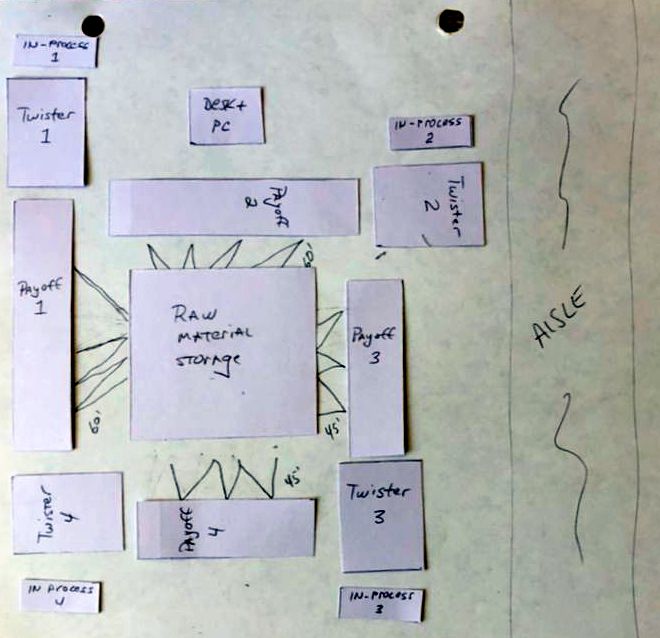

Fortunately, we can use Spaghetti diagrams to visualize Transport waste.

Current State

Future State

A Partial List, Transport Waste

- Product damage during transportation

- Use of forty foot shipping containers, placed at the far side of a parking lot, for raw material storage

- Move hospital patients from department to department

- Lack of vertical storage in warehouses increases transport path length

- Move raw material and parts from line side storage back to a warehouse.

- Conveyor within work cell

- Paper documents transported between work areas

- Machines too close together, thus impede material flow

- Product is partially processed at one location, finished at another

- Use of distant suppliers

- Move extrusion dies, gears and similar tooling from storage racks to work area

- Stage too much material “just to be safe” at a construction job site

- Move improperly stored material to a more protected area

- Poor location of line side material storage

- Safety hazard caused by fork trucks and pallet jacks (Safety hazards caused by Transport Waste)

Finally, and as a friendly reminder, please add your examples of Transport waste in the comments section below.

Next time: Inventory waste

Leave a Reply