This is the third post in a series taken from a lesson in Pyzdek Institute Lean Six Sigma Black Belt training. Future posts will continue the topic. You can find all of the articles in the series by searching this site for the title.

What do we need to produce? How many and when?

How fast do we need to produce in order to meet customer demand (Takt)? Goal: produce precisely this much just-in-time.

Takt Time

You learned about calculating and using takt time in the design a lean value stream module. It is used here when developing the continuous flow cell. You will recall that takt time, which is synonymous with cycle time in lean, is calculated as . Once this has been calculated the amount of work for each worker is determined so he can work at a constant cycle time. No extra margin “fudge factor” is allowed. In addition to takt, the team also determines the speed, degree of skill and other standards required. New workers are considered trainees until they are able to consistently produce quality work at the required rate.

As with value stream design, the work cell uses takt time as the standard cycle time. Since no fudge factor is included in the calculation, waste becomes obvious. There will also be individual differences in ability that will emerge. While all workers are required to match takt time, some people will be able to produce faster than others. Allowing them to do so in a work cell would be counterproductive, it would merely result in accumulated work-in-process inventory. The work cell must be designed to productively utilize the skills of the superior workers for the benefit of the team and the company. More about this later.

What are the requirements for materials, machines, and manpower?

Can the processes that we have meet this demand? Identifying Work Elements.

Decomposing a process into work elements helps you identify sources of waste and allocate work among people. This involves identifying and timing each work element. You will find that some of the work elements are repeated in every work cycle, while others are not. Examples of non-repetitive work are replenishing supplies or getting tools. Work cell design considers only work that is involved in every cycle. Non-repetitive work is either converted to repetitive work, eliminated, or done outside the cell.

To identify the work elements, begin by defining the scope of the work being evaluated. This will be a subset of the work done within the cell. Watch a qualified operator do the work several times. For a while, just observe the work being done to help you get a feel for what’s involved. Once you have a sense of the whole, break it down into specific elements. Write down a description of each element and have the team participate until you arrive at a description that everyone understands and agrees upon. Be sure each element description has a clear start and end point. Describe the sequence in which the elements are performed. Identify which activities are done by people and which are done by equipment. Finally, record any non-repetitive work that needs to be done outside of the cell, or which can be eliminated.

What are the specific tasks required to complete the work?

Overall cycle time for the value stream and each process within the value stream is determined by customer demand and the time available for work. This also applies to the rate at which parts are produced within a cell. Since parts are completed as work elements are performed, work elements must be timed. When collecting data on work elements the time it takes a capable worker to complete each work element must be determined. Collect actual data from various people doing the work. Work element time won’t be based on the very fastest or slowest time, rather you are looking for a representative time that can be performed repeatedly over time. The descriptive statistic most useful for this purpose will be a measure of central tendency, such as the mean, the median, or the mode.

| Process | Work Element | Person | Time 1 | Time 2 | Time 3 | Time 4 | Time 5 | Mean | Median | Mode |

|---|---|---|---|---|---|---|---|---|---|---|

| Weld + Inspect | Place in jig | A | 5 | 3 | 5 | 5 | 4 | 4.4 | 5 | 5 |

| B | 7 | 6 | 6 | 8 | 5 | 6.4 | 6 | 6 | ||

| C | 5 | 4 | 4 | 4 | 3 | 4.0 | 4 | 4 |

Table 1 shows an example of a process study which recorded the time it took three different people to place a part in a weld jig. Five times were observed for each person, the times recorded, and statistics calculated. Based on these data the team will determine the standard time for this work element. (What would you choose to be the standard time?[1]) I suggest that work elements be timed by recording several cycles with a camera and evaluating the recording off-line. You can use the video timeline to identify precisely when an operation starts and stops, or you can get this information with the pause button and a stopwatch.

Take a look at Table 1 again. Note that Worker B takes longer than either Worker A or Worker C. Such person-to-person variability is to be expected; people are different, after all. In the work cell design for multiple workers you want to arrange overlap in areas of responsibility so the faster workers can help whenever the slower workers fall behind. Lean recognizes that it’s the team, not the individual worker, that produces value. It makes no sense to have the faster workers in a cell producing at a rate that exceeds takt while slower workers produce at a rate less than takt. People must work together to help their company compete.

Once you have the cycle time data for all of the work elements, you can combine the data to determine the overall production capacity.

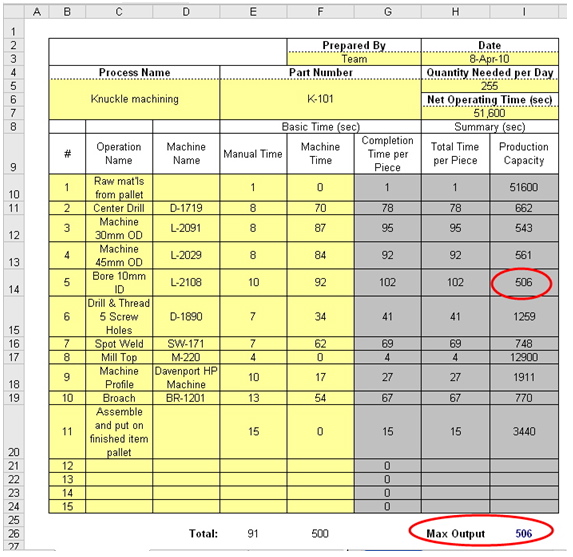

Figure 1 shows this analysis for a machining process. The production capacity (column I) is based on the net operating time per day, which does not include scheduled breaks or lunch (cell I7, 51600 seconds) divided by the total time per piece. The production capacity for the machining process is the smallest production capacity for all required operations. In this case the value is 506 units, the production capacity for the Bore 10mm ID operation. Since this exceeds the quantity needed per day of 255 (cell I5,) this process has adequate capacity, assuming unplanned downtime, scrap, etc. are held in check.

Bottlenecks

If the production capacity is less than the quantity needed per day we would have a bottleneck which we need to address so we can meet the required demand. In Lean Six Sigma a bottleneck is any process that has a cycle time that is greater than takt time. It is possible to have multiple bottleneck operations. There are several ways of breaking bottlenecks:

- Improve its cycle time. Use Lean Six Sigma, Kaizen and other methods. You should review the Production Capacity Table for the process and focus your attention on the operations with the lowest production capacity. Look at the basic time and tool change time for ideas about improving the operation.

- Improve quality. It is vital that the units produced by the bottleneck conform to requirements. Take extra care that only acceptable quality materials are delivered to the bottleneck. Aggressively address any issues with the quality of production created by the bottleneck.

- Supplement bottleneck production with purchased materials. Use a supplier to fill the gap temporarily until the bottleneck is brought up to capacity.

- Work the bottleneck longer hours. This option will require returning to batch-and-queue until a better option, such as one of the approaches above, can be implemented. The real time output from the bottleneck can be supplemented with inventory produced earlier by the bottleneck. Try to keep this additional inventory to an absolute minimum.

- Add capacity. Purchase additional equipment to allow additional production. This is usually the least desirable option because it tends to lock in the expense. If you need to do this, look into leasing equipment.

What materials do we need to have on hand in order to produce the items? (Standard Stock)

Standard stock refers to the materials that are needed to begin work within a process, such as work-in-process inventory (WIP.) The design of the work cell will influence the WIP requirements. Ideally, one piece will start at the beginning of the work cell and progress through each process step without the need to stop. However, there are circumstances that may require additional stock. For example, if a part is welded at one step and needs to cool before it can be processed through the next step. Or if there is a need to perform an inspection before the part is placed in a subassembly where it can’t be accessed afterwards. The bottleneck situation described above may require some amount of additional WIP.

What equipment do we need in order to produce the needed items?

Small, flexible/mobile, “fast-enough” machines

Equipment in work cells tends to be smaller and more flexible than the equipment used for mass production batch-and-queue operations. The machines are also often slower than those used for batch-and-queue systems. There are several reasons for this:

- Smaller machines can be placed closer together. This reduces the travel distance required by the workers. Since WIP inventory is small or non-existent, we don’t need much space between machines for storage.

- Equipment used in lean work cells can be slower, “fast-enough” is good enough. Unlike mass production equipment, the goal isn’t to produce a large batch quickly, it is to produce at the pace of customer demand, takt. This means that a machine running at a rate faster than the required rate is wasteful.[2]

- Smaller machines save space. Lean work areas often produce triple the value per square foot compared with their non-lean counterparts.

- Small machines can be moved more easily. A work cell can be quickly reconfigured by rearranging equipment to produce a variety of different parts.

- Flexible machines must be easy to set up fast. If changeover and setup times are low, it is easier to produce a variety of parts in small quantities.

- Small, slower, and more flexible machines are less expensive, easier to operate, and easier to maintain.

Equipment is also used in office environments. Computers, printers, fax machines, file systems, desks, tables, mail carts, etc. are needed to perform work in an office. The lean equipment principles also apply here.

Autonomation (Jidoka)

Autonomation is Taiichi Ohno of Toytota’s word to describe a production system that mimics the human autonomic nervous system, i.e., it automatically adjusts to external and internal conditions. For example, when we get too hot, our body automatically reacts to cool us down; we don’t have to think about it. Similarly, production systems should react to customer demands, increasing production when demand goes up or decreasing production when demand goes down. They should react to Work-in-Process inventory buildup by producing less or producing on a different schedule. Lean mechanisms to accomplish this include Takt time, visual controls, pull systems, exploiting constraints, etc.

Actually, this concept was embodied in the very first product made by Toyota, a loom. From an early age Sakichi Toyoda worked on improving looms. In 1891 he obtained his first patent for the Toyoda wooden hand loom. Among the innovations was the feature that the loom stopped if a thread broke. It can be argued that this invention led directly to the formation of the Toyota automobile company. A company was founded in 1926 as Toyoda Automatic Loom Works, Ltd. by Sakichi Toyoda. In 1933, the company established its automobile department, led by Kiichiro Toyoda, the eldest son of Sakichi Toyoda. This department was spun out as Toyota Motor Co., Ltd. in 1937 and is now the well-known Toyota Motor Corporation.

Autonomation within a work cell is used to eliminate the need for an operator to stand and watch a machine as it does its work. Work cell equipment is intelligent in the sense that it stops and signals when an operation is complete, or if there is a problem.[3] Although operators often load the machines, the machines usually unload automatically. More importantly, after the operators load and start the machines, they move on to other activities in the cell rather than watching or tending to the machines.

Modifying equipment to use Jidoka is usually quite simple and inexpensive. Microswitches, simple sensors, light beam and other simple mechanisms are commonly used for the purpose. Poka-yoke is Japanese for mistake-proofing. These devices are used either to prevent the special causes that result in defects, or to inexpensively inspect each item that is produced to determine whether it is acceptable or defective. A poka-yoke device is any mechanism that either prevents a mistake from being made or makes the mistake obvious at a glance.

[1] I would choose 5 seconds. It is close to the overall mean, and it’s the average of the three medians and also the average of the three modes.

[2] Cost accounting systems are often designed to measure output from individual pieces of equipment rather than from value streams. These systems need to be modified to accurately measure the lean value stream; failure to do this can undermine the entire Lean Six Sigma program.

[3] This is an example of poka-yoke or mistake-proofing, a topic discussed at length later in this course.

Leave a Reply