When we talk about statistical knowledge in Lean Six Sigma, we’re addressing the critical component that drives success in Lean Six Sigma certification. For those who have ventured into this area, you’ll understand that Lean Six Sigma isn’t merely a collection of tools or techniques; it’s a mindset that drives operational brilliance. And at the heart of this mindset lies one pivotal component: statistics.

Why Statistical Knowledge in Lean Six Sigma Matters

In Lean Six Sigma, we aren’t just guessing our way to solutions. We’re methodically identifying issues, analyzing root causes, implementing solutions, and ensuring the longevity of improvements. This is virtually impossible without an in-depth grasp of statistical concepts.

Statistical know-how serves as the bedrock for data-driven decision-making. Unlike traditional problem-solving methods that might rely on intuition or anecdotal evidence, Lean Six Sigma demands empirical proof. It hinges on facts, data, and rigorous analysis. By mastering statistics, practitioners can pull out meaningful insights from data (which is incredibly useful), thus enabling them to spot patterns, comprehend variations, and draw conclusions leading to effective solutions.

Understanding Variation Through Statistical Knowledge in Lean Six Sigma

One primary goal within Lean Six Sigma is to minimize variation within processes. But to achieve this goal effectively (and sustainably), you must first grasp what variation entails—how to measure it and how to control it—and this is where statistics become essential.

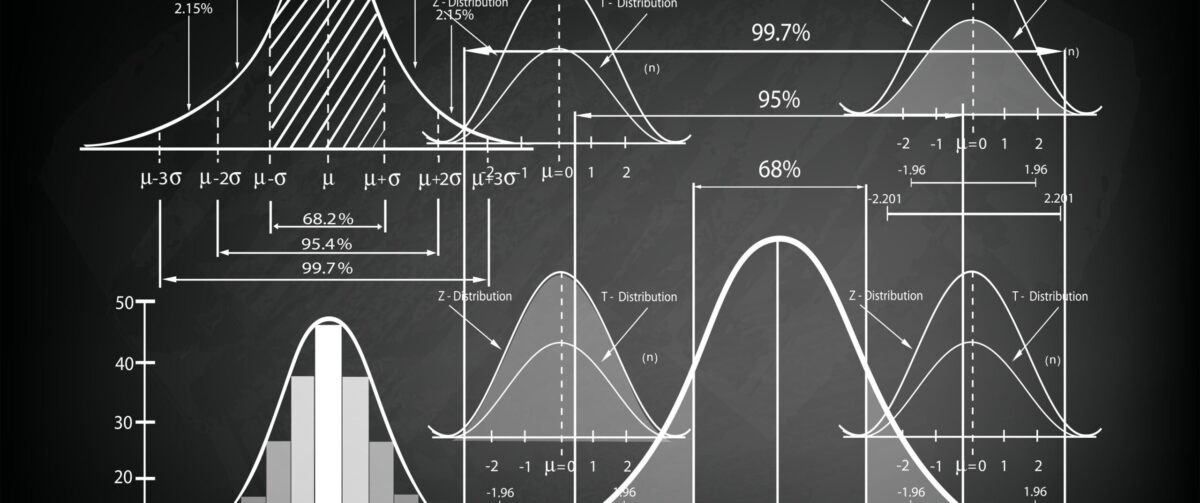

Through statistical tools such as histograms (which give us visual representations), control charts (that track performance over time), and hypothesis testing (for making informed decisions), practitioners get a clear snapshot of how processes are performing over time. For instance, control charts help distinguish between common cause variation (the natural fluctuation within a process) and special cause variation (unexpected deviations). By pinpointing these variations accurately (which tends to be crucial), Lean Six Sigma professionals can implement targeted interventions addressing root causes rather than applying short-lived fixes.

Applying Statistical Knowledge in Lean Six Sigma’s DMAIC Process

Data collection isn’t simply about gathering numbers; it’s all about capturing the right kind of data in the most appropriate manner possible. Statistically sound data collection methods ensure that the information used for analysis is accurate (as well as reliable). Practitioners often employ statistical sampling techniques for collecting representative data—this reduces bias significantly while ensuring conclusions drawn reflect reality quite closely.

Once collected, statistical analysis helps uncover trends or relationships otherwise hidden within raw data. For example—regression analysis allows us understanding relationships between different variables while hypothesis testing aids in making informed decisions regarding process changes. Without solid command over these techniques though—you’d essentially be navigating blindly relying more on gut feelings rather than evidence-based decisions!

DMAIC: A Journey Driven by Statistics

The DMAIC process—which stands for Define Measure Analyze Improve Control—is fundamentally rooted deeply within statistical knowledge:

- Define: Understanding customer requirements translating them into measurable goals.

- Measure: Collecting current process-related data using statistically sound techniques ensuring accuracy.

- Analyze: Utilizing various statistical tools identifying root causes behind variations/defects.

- Improve: Implementing statistically-backed solutions ensuring improvements aren’t mere temporary fixes but lasting ones instead.

- Control: Monitoring improved processes through control charts/statistical tools sustaining gains achieved initially.

Each stage underscores the necessity of possessing strong statistical knowledge, proving once again why Lean Six Sigma is as much a quantitative science as it is a quality management philosophy.

Bridging Theory with Practice

Many Lean Six Sigma practitioners face challenges transitioning theoretical knowledge into practical applications primarily due to a lack of proficiency around stats themselves. It’s not enough to merely understand the principles underlying Lean Six Sigma; you need the skill to apply these principles and tools in real-world scenarios to create true value. Concepts like standard deviation and process capability indices might seem abstract at first but provide the critical information needed to make long-lasting improvements in practical applications.

Conclusion – Pathway Toward Mastery

On your journey to becoming a proficient Lean Six Sigma professional, acquiring robust statistical knowledge is not just beneficial—it’s absolutely essential. This knowledge equips you to comprehend, analyze, and control processes in ways that intuition alone could never achieve. The difference between guessing and knowing, and between temporary fixes and truly permanent solutions, lies entirely in this knowledge!

Lean Six Sigma focuses on creating lasting change rooted in solid statistical analysis. Whether you are starting fresh or deepening your existing expertise, investing the time and effort to master statistical knowledge becomes an indispensable cornerstone that supports every improvement, success, and breakthrough.

Dr. W. Edwards Deming famously said, ‘In God we trust; all others must bring data,’ highlighting the importance of data interpretation and guiding us toward the essence of quality and continuous improvement…

Leave a Reply