I heard a speaker talking one time who said, “if you improve an organization’s productivity by 3 percent each month, you will double your productivity in 25 months.” He is right, you will double your productivity, but the challenge will be keeping those gains.

I worked with another Lean Six Sigma Black Belt in our organization to create a program we called, Simple Kaizen. It was designed to elicit small improvements from the front-line staff, vet them, then update the process to include those improvements.

We started by building a training deck and training the managers on how to manage this process. We met with them and stressed the importance of follow-through on every aspect of the program, for example:

- Start with a clear goal for the suggestion box. For example, “we want to reduce the time it takes to perform our tasks in the process.”

- When a staff member makes a recommendation, you have to review it in a timely manner, determine if it makes sense, then meet with the employee to let them know the result.

- When someone makes a recommendation that is inserted into the process, you need to recognize that employee and document the results.

- When you make a change to a process, you need to make sure everyone is trained on the new process steps and that all documentation is updated.

Most people have been part of a suggestion box program during their career. There was always lots of fanfare at the beginning, however, in the long run, these programs fail miserably. People make suggestions and never hear anything. They have no idea if their suggestion was considered good or bad. The general consensus becomes, “Why bother? You never hear what the results are anyway”. After that, the number of suggestions quickly trail off to zero.

The problem was management follow through. It took time and energy from management to review each recommendation and follow up with the employee to let them know if the suggestion was worthwhile. Even if management decided a suggestion was not worth the time to implement (for any number of valid reasons), they still needed to follow up and let the employee know why.

If an employee made a suggestion that should be implemented in the process, it was even more important to follow up. First of all, the employee should be praised for the suggestion (They might have better suggestions in the future). You would never know that if they are not praised for the current suggestion. Also, you need that person’s help to communicate the change to others who used the process. This was important because the person who recommended the change had “ownership” of the change. They would be instrumental in overcoming any objections others might have about the proposed change and in training staff on the new process steps.

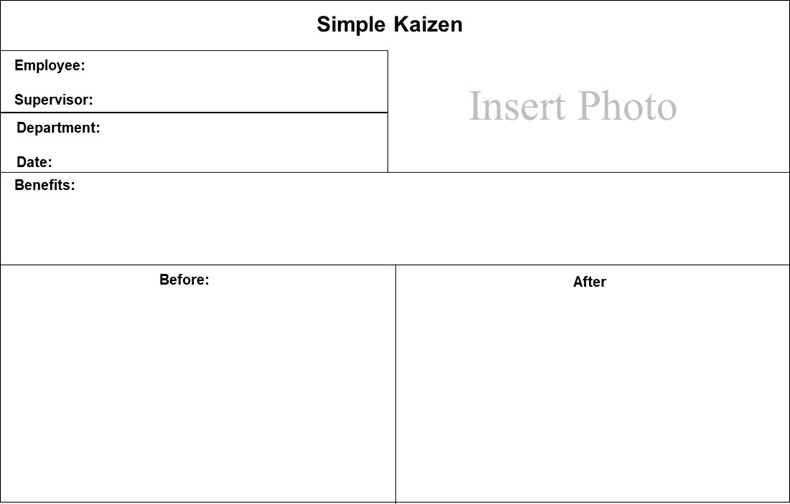

Once the change was implemented, management needed to ensure the employee was recognized publicly. It could be something as simple as an Amazon or Starbucks gift card or just visual recognition. We did this by taking a simple template, such as that shown below. We completed the text part, inserted a picture of the employee and posted it in a part of the business where people congregated. People saw this recognition and thought, “I want to get my picture on the wall too.”

The first time we implemented this process it failed miserably. I emphasized with the manager how important it was to follow through with the team on each suggestion. She didn’t, so the program died. The second time I tried this we had similar results. After that, I sat down and strategized with my black belt on what we did wrong and how we could make it better in the future.

The third time it worked great. We worked with a group of call center agents in our Tampa office. We spent more time working with the manager to get the process right and training the staff on what to expect. Their manager was yellow belt trained and needed our help so she was willing to do whatsoever we said. We asked her what she was hoping to gain from the suggestions and she stated, “we need to do more with less. We are getting more work but have no opportunity to hire additional staff. I currently have staff working overtime just to keep up.”

We settled on the goal of reducing the time to take and document a client call, what we would call average handle time or AHT. I expressed to her that the follow through on suggestions was the most important part of the next phase. She held a meeting to explain what she wanted to do with her entire staff during their morning huddle meeting. During the first week, the manager received thirteen suggestions. Seven she described as “blah” with little to no impact on the timing in the process. She met with each employee to explain why she would not move forward with their improvement idea. Four were described as, “sounds interesting but I need to get more information”. Two were described as “no brainers” which should be implemented immediately.

I asked her about the no brainers and she said that each agent has to put their phone number in the call ticket they create. The system had the capability to pre populate this information but it was never configured that way. She stated it would take one agent a couple of hours to configure the phone number field for all of her agents. The second improvement was to populate another table in the software that would automatically display a description when they entered the appropriate code. In this case, the ICD10 code. This took a little longer to complete as they needed help from someone in the IT group. After two weeks both changes were implemented in the system with an average savings of 17 seconds on each call. It didn’t sound like much but when you took 4,200 calls a month, it equated to an additional 238 hours of productivity over the course of a year.

After two weeks in production, the manager completed the template shown above and posted it in the lunchroom for the two production changes. She also held additional meetings on the four suggestions which required more analysis and found that one of these was also worthwhile. This improvement shaved another twelve seconds off of the average handle time equating to an additional savings of 168 hours per year.

The three changes discussed here were all changes to the configuration of the software used, making their insertion into the process fairly simple. Changes to the process which required a different action by staff members was a little more complex.

Each Agent had scripts of questions they would ask for certain types of issues. Once they figured out what the issue was, they would bring up the script, ask the questions and populate the customer relationship management (CRM) data fields with the responses. The script, however, was not aligned with the sequence of fields in the software, requiring that each analyst scroll back and forth in the software to populate the correct fields. The suggestion was to change the sequence of questions in the script to match the sequence of fields in the software. It took about a week to update all of the scripts, get them approved, and train the staff. This improvement shaved another 12 seconds off of the average handle time for a call.

As you can see, this technique can be very successful in reducing the cycle time of processes. In this case, the team gained over 574 hours in productivity for a year. The key was to take time to train the manager on the process and ensure follow-up with the Agents.

What is your experience working with simple Kaizen concepts? Let me know in the comments.

Leave a Reply