A typical Six Sigma project adds between $145,000 and $250,000 to the bottom line. These numbers provide useful guidelines to the Black Belt for breaking the project down to manageable size. True Six Sigma projects are neither too large nor too small.

It’s rare that the project as it’s initially proposed will be the right size. Projects are usually too big. I call these “world hunger” projects because, although their objectives are laudable, chances for success are limited.

The solution is not to abandon lofty goals but to break the problem down into smaller pieces. In Six Sigma project management, this is accomplished by creating a work-breakdown structure (WBS). The WBS is designed to develop work subplans by breaking down the larger project into smaller components. When the work has been accomplished and the results reintegrated, we’ll have reached our goal.

The creation of work-breakdown structures involves a process for defining the final and intermediate products of a project and their relationships to one another. Defining project activities is complex. It’s accomplished by performing a series of decompositions, followed by a series of integrations. For example, a project to develop an SPC software application would disaggregate the customer requirements into very specific engineering requirements. The customer requirement that the product create X-bar charts would be decomposed into engineering requirements such as subroutines for computing subgroup means and ranges or plotting data points. Integration would involve, for example, a user interface linking the various modules to produce an X-bar chart and display it on the screen.

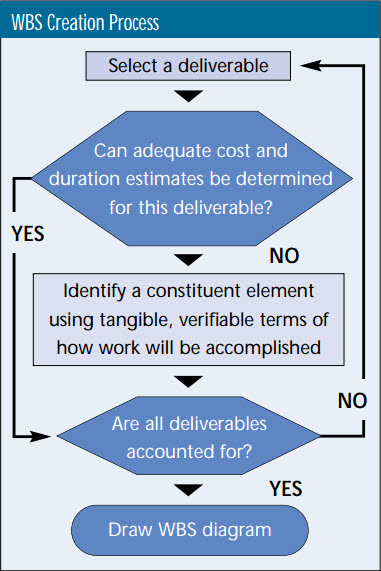

The project deliverables expected by the sponsors are initially defined in the scope statement. Methods of measuring and tracking the creation of the deliverables are developed. For most Six Sigma projects, major project deliverables are so complex as to be unmanageable. Unless they’re broken into smaller components, it isn’t possible to obtain accurate cost and duration estimates for each deliverable. WBS creation is the process of identifying manageable components or subproducts for each major deliverable. The process is described by the flowchart shown in Figure 1.

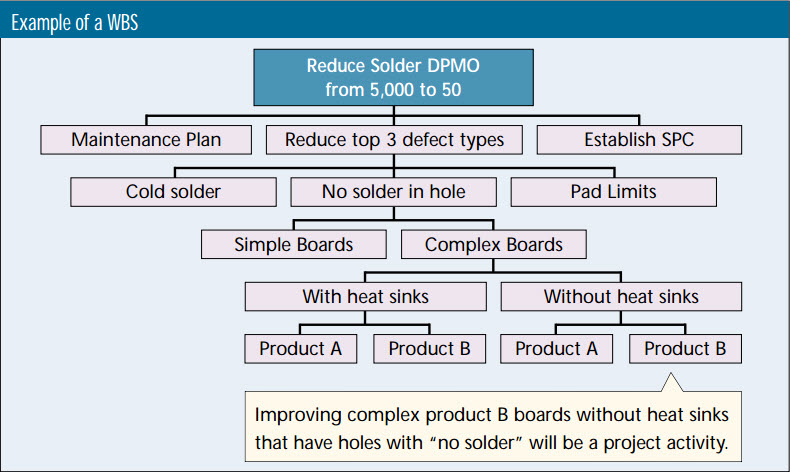

Figure 2 shows a WBS for a Six Sigma project to improve the quality of soldering. The project team continues down a branch until a particular type of solder problem can be assigned to a subproject team that includes a design engineer and a process engineer. For simplicity, only the WBS branches of complex boards for the problem labeled “no solder” are shown. On real Six Sigma projects, the WBS can become quite complex, resulting in unwieldy WBS drawings. Like a flowchart that becomes too large or complicated to fit on a page, WBS drawings often continue onto “off-page connectors,” which are circles with an alphabetical or numerical reference to a lower-level WBS chart.

The WBS process continues down to the level where the team feels it can very clearly budget, schedule and assign activities. Problems defined to this level are sometimes referred to as “tiny.” The basic idea is to divide and conquer larger issues by reducing them to simple mini-projects. Of course, the individual solutions must be re-integrated into a complete solution, which must then be tested as a whole system.

Leave a Reply