In my Six Sigma Leadership Process post I described the leadership process at the highest level, the L-1 level. I mentioned that the Improve phase of leadership required mapping core processes to an actionable level, a level where the Process Excellence Leadership Team–the PELT–could identify the critical to quality drivers in the process. In this post I will describe an approach for actually doing this, which is known as “L-Mapping.” L-Maps are a type of simple process map used to obtain an understanding at a very high level of key business processes. They are especially useful to leaders who want to understand the hierarchy of interrelated processes that make up the business.

The traditional way businesses are organized is the functional hierarchy. Tasks are divided among specialists who have, more or less, monopolies on a certain set of activities. For example, finance and accounting has exclusive authority over budget approvals, engineering over product design decisions, marketing over advertising content, and so on. Within a given function decision making authority is delegated from a single person at the top downward to subordinates. In larger organizations this functional/hierarchical arrangement may exist in several different business units, each focusing on a particular market. This view of the business is often called a “silo organization” because the organization chart visually resembles the grain silos seen in farm country.

Problems with the Silo Organizational Form

Despite the tremendous success of the silo organizational form, it is not without problems. One common problem is that customer value is not created within any given silo. Instead, value streams flow across several silos, drawing a bit of value from each. These customer value streams are called core processes in process excellence work. In a traditional organization core processes are not managed per se. In other words, they are not specifically designed, the key process outcomes and indicators are not defined or measured, and no one is held accountable for process performance. As you might guess, this results in inconsistent performance at best and it sometimes leads to disastrous results.

Let’s look at an example of how L-maps can help remedy this situation. Figure 1 shows an L-1 map for a software company. Despite its simplicity, such a map requires a considerable amount of discussion and thinking on the part of the senior leadership team. Obtaining a shared vision that this map accurately describes the business is a valuable exercise. It’s an entirely new way of looking at the business from the process perspective. Functional leaders are often puzzled and confused by this perspective and require training to understand it.

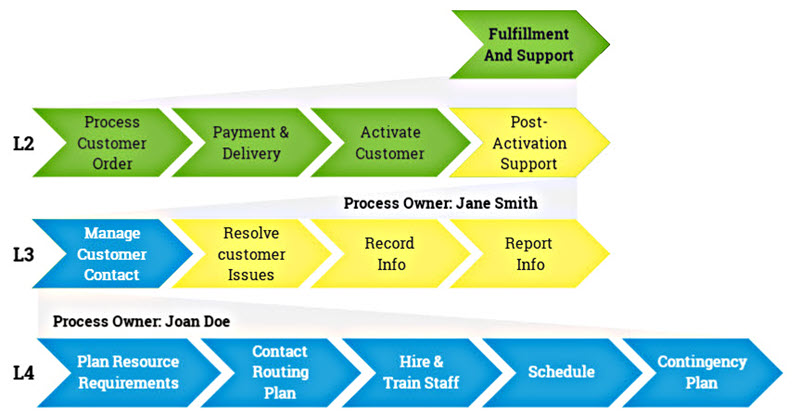

Organizations that take process excellence seriously will identify owners for each process on the L-1 map. While the details of the process owner’s duties and authority vary from one organization to the next, there are some common features. Process owners are responsible for defining the process in detail, for establishing performance measures, and for working with functional managers to achieve process excellence. Part of this task involves defining their process at greater levels of detail. This is shown for the Fulfillment and Support process in Figure 2.

At some level the L-Mapped process will become “actionable.” This means simply that the owner of the process at this level will be able to determine how to improve their process. Improvement might involve Six Sigma projects, or it may involve some other method of improvement such as a traditional project, continuous improvement, local work-group activities, etc. In the opinion of Joan Doe, her process map provided the guidance she needed to identify her process improvement strategies.

Note that Figures 1 and 2 only drill down along a single path for each level. The entire set of L-maps that define all of the top level processes will be quite large at the L-4 level. Consequently, leadership will need to develop reporting systems that focus their attention on the vital few improvement projects and activities that implement their strategies and deploy their goals and metrics.

Conclusion

Don’t let the simplicity of L-Maps fool you. This tool provides an anchor that employees and team members can use to determine how their work impacts the performance of the company. The activity of creating L-Maps helps the entire management team develop a shared vision of what the organization really is. It links projects and local plans to higher level goals and results. In short, it’s extremely useful in a wide variety of ways. Once you’ve incorporated this simple tool into your routine, you’ll wonder how you got along without it.

Do you have more questions about L-Maps or are interested in Six Sigma Training? Contact Pyzdek Institute today!

Reproduction allowed if no changes are made to content and you link to this article.

Leave a Reply