Six sigma isn’t just about quality for quality’s sake.

Your employer, Peerless Systems, acquired Acme International for its technology. But your leaders want more than just Acme’s technology; they also want Acme to be successful in its own right. But Acme has problems. Acme, it seems, is still operated as a traditional three-sigma company. Peerless has long since moved to six sigma and beyond, and you played an important role in making that happen. Your new challenge is to lead Acme from three sigma to six sigma. It’s what you’ve been waiting for your entire career—welcome to senior leadership!

You bring your staff together to establish a baseline. Bob, the vice-president of marketing, says, “We’re losing customers due to poor quality, and our competitors are killing us on price.”

Ann, your director of quality, is next. “When Bob told us about the quality problems, we increased inspection and testing, ” she says. “Field failures dropped, but (of course) costs increased.”

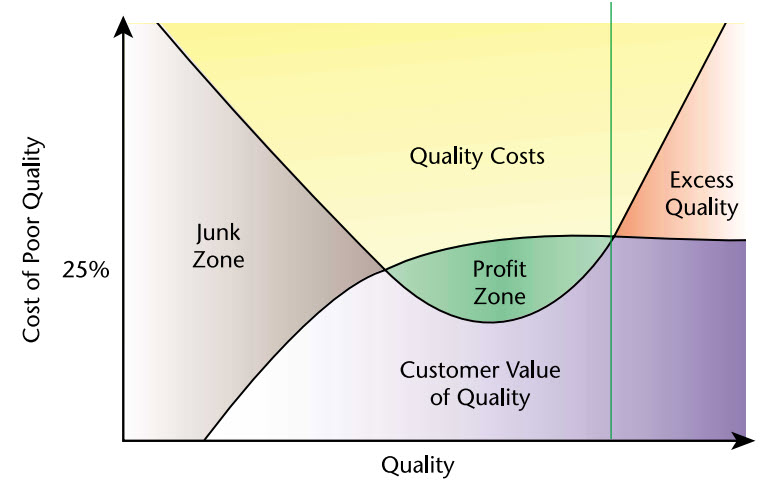

Lorraine, vice-president of finance, shows Figure 1. “My staff and I believe that the customer places a certain value on quality,” she states. “At first, our quality was too low, and the customer wouldn’t buy our products. When we improved our quality, we also increased our costs, but the customer wouldn’t pay the higher prices we had to charge. We’ve found that profitability is maximized when total cost of poor quality is about 25 percent of sales. The problem is that there is very little profit, even at that cost level.”

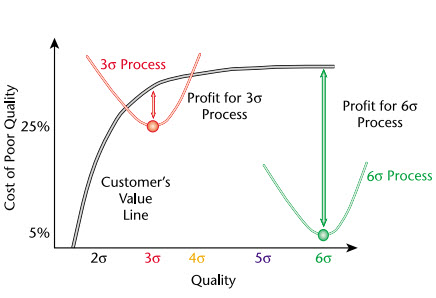

This all has a familiar ring to you. You know that the typical three-sigma company spends about 25 percent of each sales dollar on the cost of poor quality. Before starting the six sigma journey, Peerless was in similar shape. You’ve prepared the slide shown in Figure 2 to illustrate the difference between three-sigma and six-sigma quality for your staff.

“Right now, our business is only capable of operating at a level equivalent to about three-sigma quality,” you explain. “Trying to get better quality out of our existing systems only adds costs. We must develop new systems that deliver better quality and lower costs simultaneously. We need six sigma systems.”

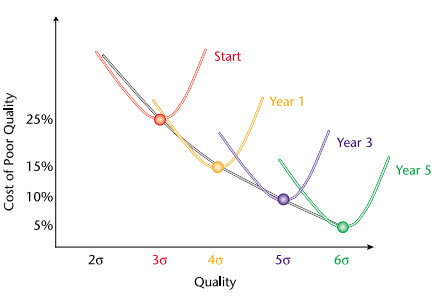

You go on to describe the differences between six sigma systems and three sigma systems, and the importance of six sigma to Acme. You tell them that six sigma is not a destination, but a journey of continuous improvement. Of course, Acme won’t go from three sigma to six sigma in one big jump. Instead, overall performance will move from three sigma to four sigma, then to five sigma and so on as people are trained and systems redesigned and improved. Figure 3 illustrates the expected progress toward six sigma.

You summarize by telling your staff that six sigma is not about quality for the sake of quality; it is about providing better value to customers, investors and employees. Paraphrasing the Chinese philosopher Lao-tzu, you announce, “Six sigma is a journey of a thousand miles. Creating a roadmap that links customer satisfaction, quality and costs is the first step.”

Leave a Reply