-

Three Key Benefits of Six Sigma Training to Organizations

Initially, six sigma functioned as a tool for reducing waste and costs associated with production. Over time, it evolved into one of the most important strategies that businesses use to produce goods as per the customer’s specifications. Most companies enroll their employees for six sigma training to improve business effectiveness. Through training, employees become efficient…

-

Train To Apply Lean Six Sigma To CMMI Process

Getting users and contractors on the same page regarding software requirements can be a major challenge that disconnects the software development process. Scenario: you cannot populate your new database with software data from the software engineers because the data doesn’t exist. The manufacturers (contractors) did not foresee the need to keep the metrics. Do you…

-

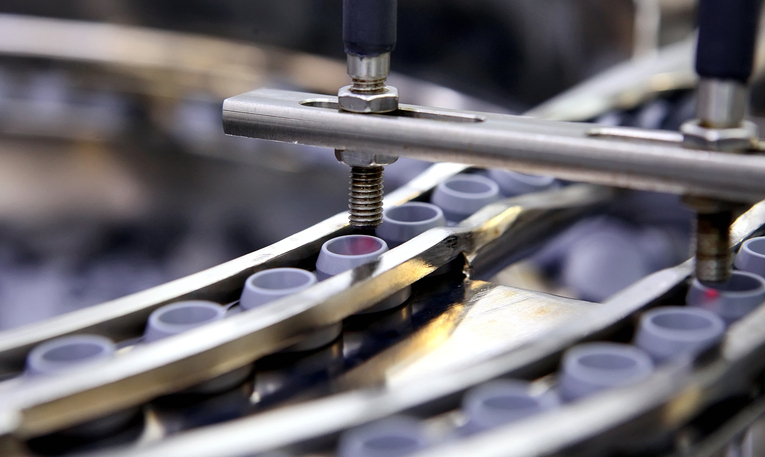

Agile Manufacturing Rebounds – Are You Ready?

Agile manufacturing is poised for a big comeback. Fully 50% of the 2014 Industry Week Best Plants class reported “significant” implementations of agile manufacturing across their operations, which represents a sharp uptick after a three-year decline: This rebound undoubtedly reflects the need for many organizations to pivot in response to growing market volatility, but it also suggests that agile manufacturing will…

-

Meet the 2015 IndustryWeek Best Plants Finalists Who Use Six Sigma To Deliver Quality & Value

“IndustryWeek” has recognized twenty North American manufacturing facilities as finalists in the 2015 IndustryWeek Best Plants competition. They range from Mexico (Batesville, Chihuahua – Chihuahua, Chihuahua) to Canada (New Flyer Industries – Winnipeg, Manitoba) and all across the United States, but despite the geographic variation, one trait they all share is a commitment to Six…

-

Practical Application of Lean Six Sigma in Reducing Cycle Time

The principles and tools in Lean Six Sigma are the most methodical and fruitful strategy to the challenge of cycle time reduction. However, managers need to understand that success in this strategy requires commitment. Cycle time reduction using Lean Six Sigma is not a quick fix and cannot be effective if only used occasionally. Success in…

-

Lean Six Sigma: Managing Change in the Manufacturing Revolution

Introduction of new technologies in the manufacturing industry, has left a gap between robotic process automation (RPA) and human intelligence. The forces promoting global manufacturing sector change since the late 20th century, such as inventory flows, skilled and semi-skilled labor, and technological innovation, continue to impact production line operations. Solutions to managing change in the…

-

‘Lean Six Sigma’ Comes to the VA: Collins Cheers

Problems at the VA The Veteran’s Administration healthcare system has been in the news for decades. The system is routinely condemned, at best as inferior and, at worse, even nefarious. There has been one account after another of operations performed on the wrong organ or limb, the reuse of disposable medical supplies like needles, and…

-

Three Ways of Improving Hospital Performance With Lean Six Sigma

The Lean Six Sigma Training developed by Thomas Pyzdek is a comprehensive approach to helping improve your business process. In the health care system, four forces have converged making care delivery more difficult than it has ever been. These include: Aging baby boomers In the next two decades, the baby boomers will become the greatest…

-

Industry Week Asks: What is the Continuum of Quality Management? (Part 1)

Recently, manufacturing publication Industry Week presented a two part series that asked the question: What is the Continuum of Quality Management? Part one of the series explored the organizational structure, competence assurance, and procedural adherence of eight different organizations, and found the following:

-

Manufacturing Plants: Are Your Scrap Metrics Lying About What Happens on the Shop Floor?

What is the most important thing about every metric used in a manufacturing plant? According to Larry Fast, in an article published in Industry Week, the answer to that question is: That the metric tells the truth about what is going on in the shop. The second most important thing, you ask? That metrics be…