Your cart is currently empty!

The Leadership Process

Leading an entire organization is a daunting challenge. One must keep everyone happy. A delicate balancing act, to say the least. We Six Sigma practitioners are often quick to criticize leaders for not properly supporting our efforts. But what if you were asked by a committed leader for advice on how to actually use Six…

How to Calculate Process Yields

Sam handed Peter a computer printout and asked, “If the yields are so high, why is my efficiency so low?” Peter, a Lean Six Sigma Black Belt, studied the report for a moment and then nodded. “Let me show you what’s going on,” he said as he picked up a marker and drew a diagram…

Six Sigma Roadmap for Small Businesses

Many Six Sigma experts have expressed doubt that Six Sigma can be used effectively in small, or even in some medium-sized, organizations. However, while the approach to deployment must be modified, it is possible for small businesses to successfully implement Six Sigma. Here is how. At the outset, several givens must be in place: All…

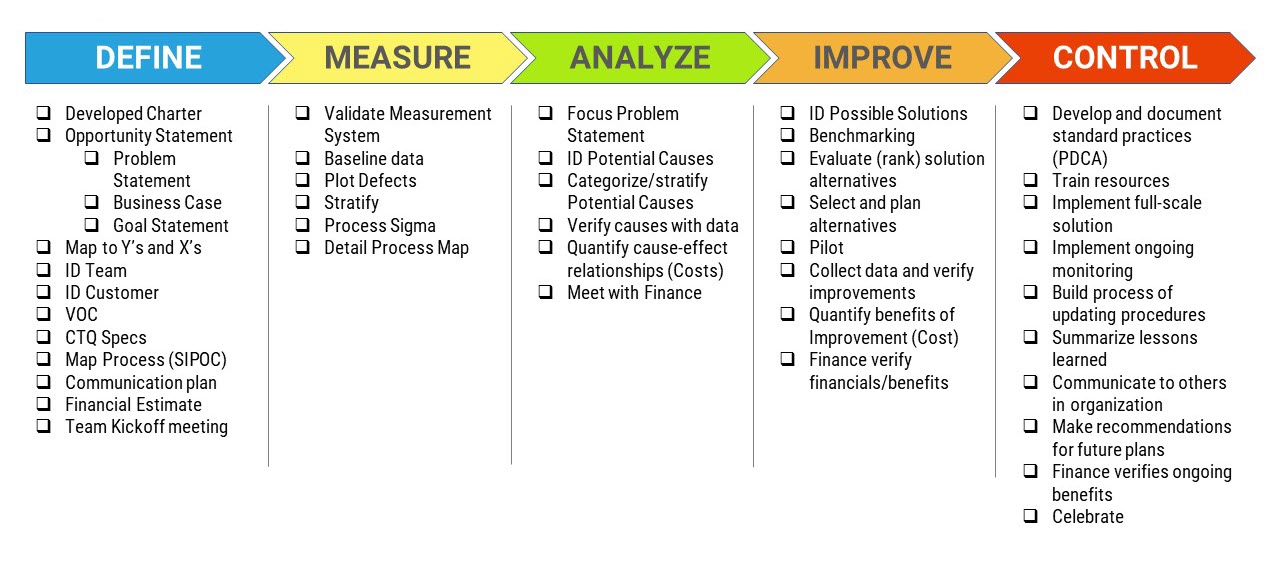

DMAIC and DMADV

The tools of Six Sigma are most often applied within a simple performance improvement model known as Define-Measure-Analyze-Improve-Control, or DMAIC. DMAIC is summarized in Table 1. DMAIC is used when a project’s goal can be accomplished by improving an existing product, process, or service. The question is often asked: What is DMAIC Methodology? The chart…

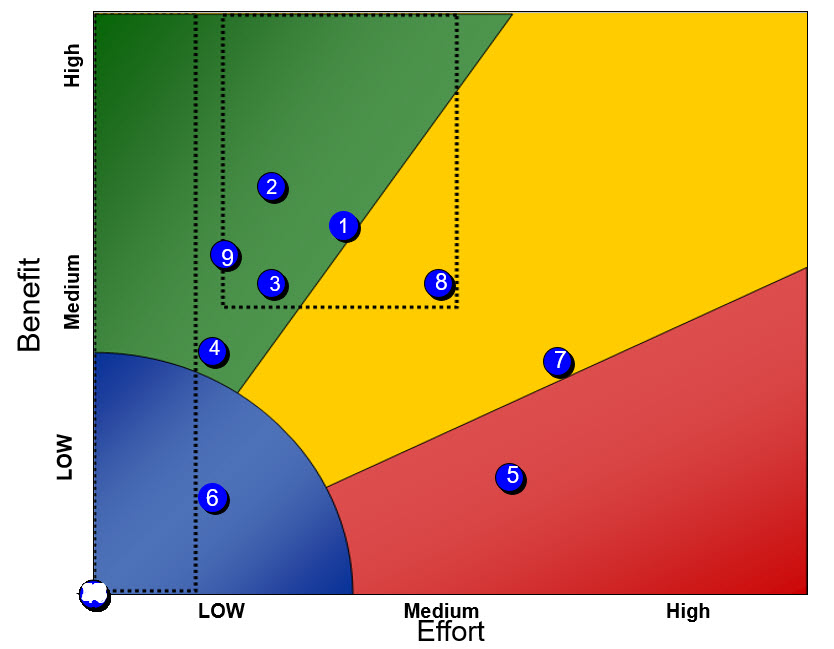

The Benefit Effort Matrix – A Tool to Determine Where to Apply Your Resources

An excerpt from my latest book, Everything is a Process. Available on Amazon. I have twenty potential projects at my company. Which are the ones that provide the greatest benefit to the company and should be completed first? Most people have heard a quote similar to that above. Where is the best place to spend…

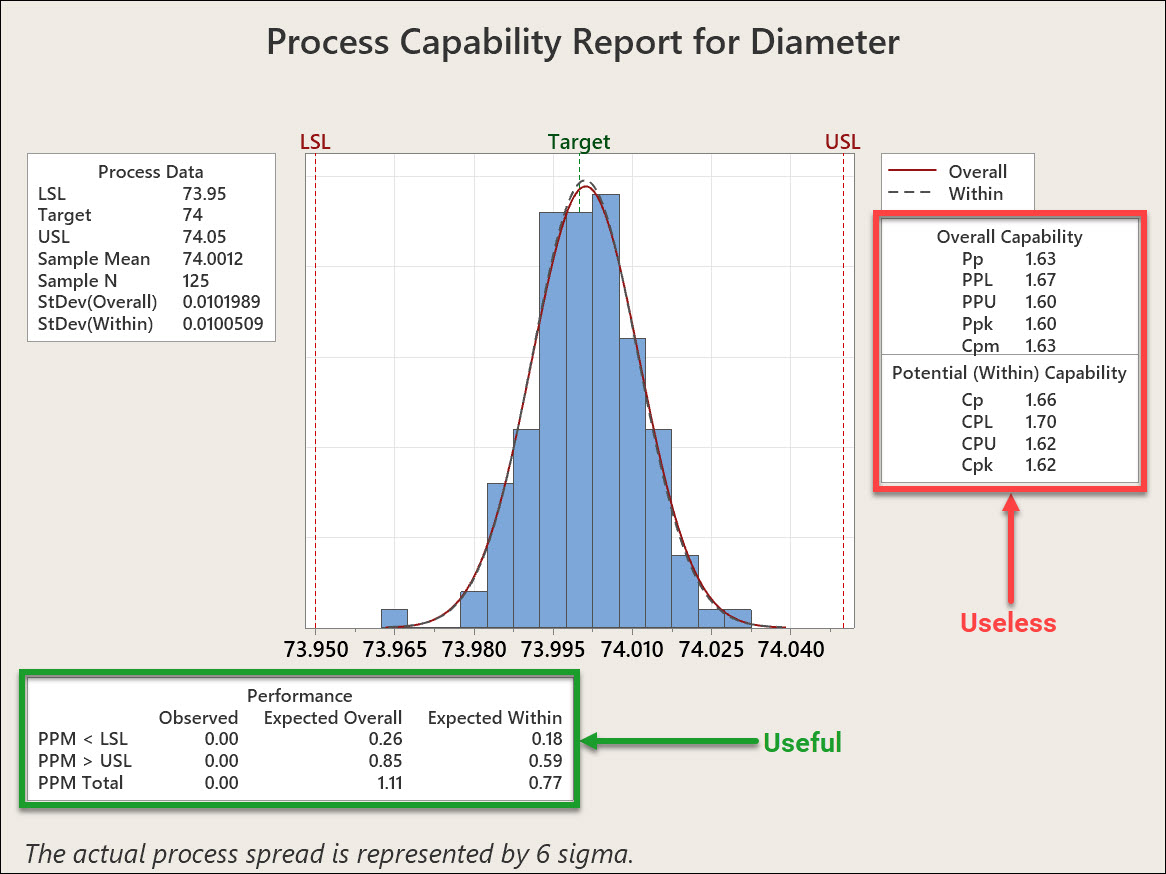

It’s Time to Ditch Process Capability Indices

Process capability indices (PCI) have long been popular with many quality professionals. But they’ve also been controversial and a number of reputable experts have advocated that they be abandoned.[1] I tend to agree. Maybe it’s time to ditch process capability indices. Here’s the good, the bad, and the ugly of PCIs. The Ugly of PCIs…

Process Capability-Let’s Skip the Jargon

To many quality engineers and managers, process capability is a jumbled confusion of ideas expressed in jargon that only the anointed can understand. Let’s skip the jargon. Imagine the following scene. The boss rushes into the quality director’s office. He’s obviously distraught. (Boss enters, walking quickly from stage right.) Boss: “Jane, we’ve got a serious…

An Acceptance Sampling Question

This thread recently appeared in myASQ: Question by Aju: Hello Team, We have a situation where we did double sampling on Incoming parts from a Supplier(Machine shop). The lot was accepted and released to Inventory. These parts then later got assigned to WO and during assembly, the Manufacturing team found one non-conforming part (missing slots).…

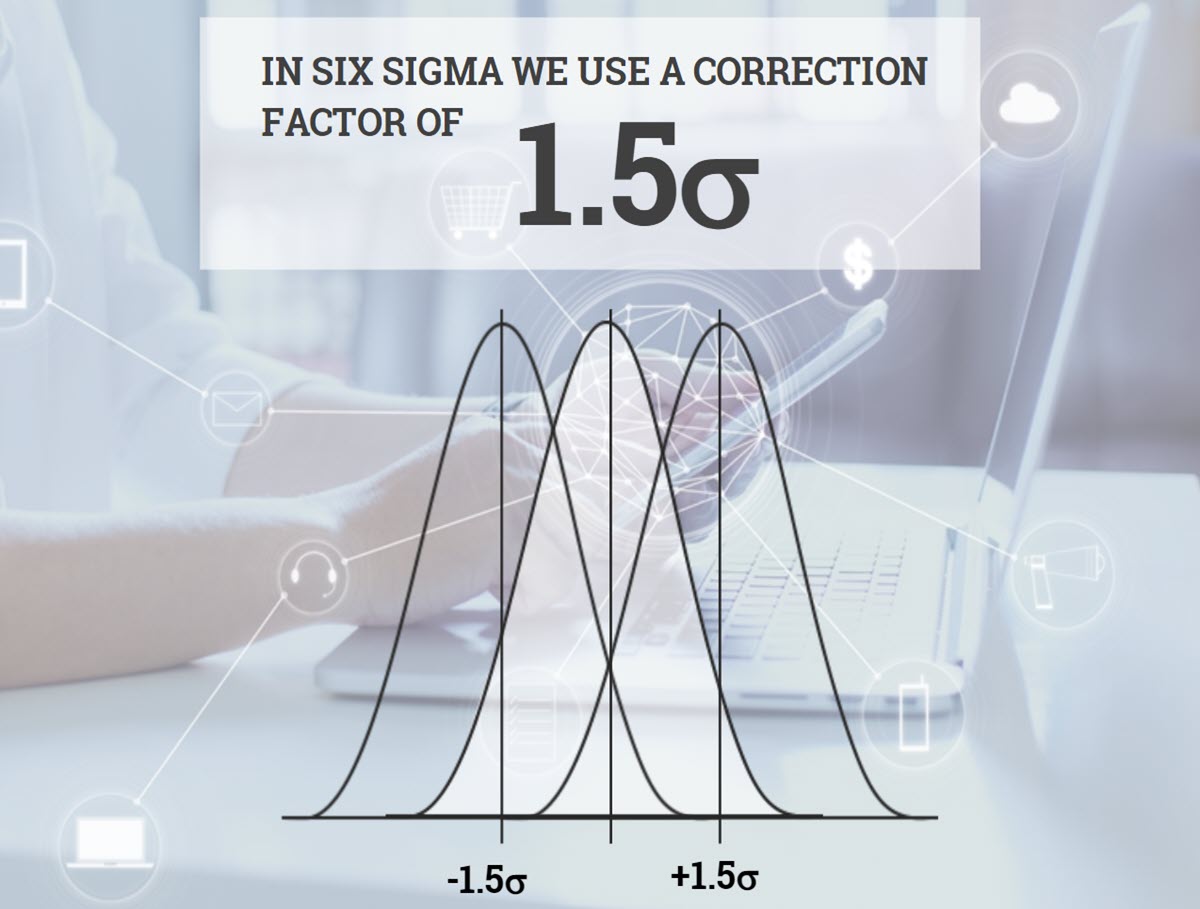

It’s Time To Ditch the 1.5-Sigma Shift

One of Six Sigma’s most hotly debated features is the infamous 1.5-sigma shift. Here’s how it works. In Six Sigma we assume that the customer’s actual experience will be worse than what we predict during capability analysis. We add a “fudge factor” that assumes that the process will shift by approximately 1.5 standard deviations. I’ve…