Your cart is currently empty!

Top 5 Industries Hiring Lean Six Sigma Experts Today

In today’s competitive market, Lean Six Sigma has become a vital tool for businesses striving to improve efficiency, reduce waste, and enhance quality. Companies across various sectors are actively seeking Lean Six Sigma experts to streamline operations, lower costs, and boost performance. Wondering which industries are the most eager to hire professionals with these skills?…

How Design of Experiments (DOE) Enhances Problem Solving in Six Sigma Projects

When we really get into the nitty-gritty of Six Sigma’s powerful methodologies, few tools are as remarkably impactful as Design of Experiments (DOE). Six Sigma is about eliminating guesswork and embracing data-driven decision-making, and nowhere is this more evident than in the application of DOE. In this post, I’ll show how DOE serves as a…

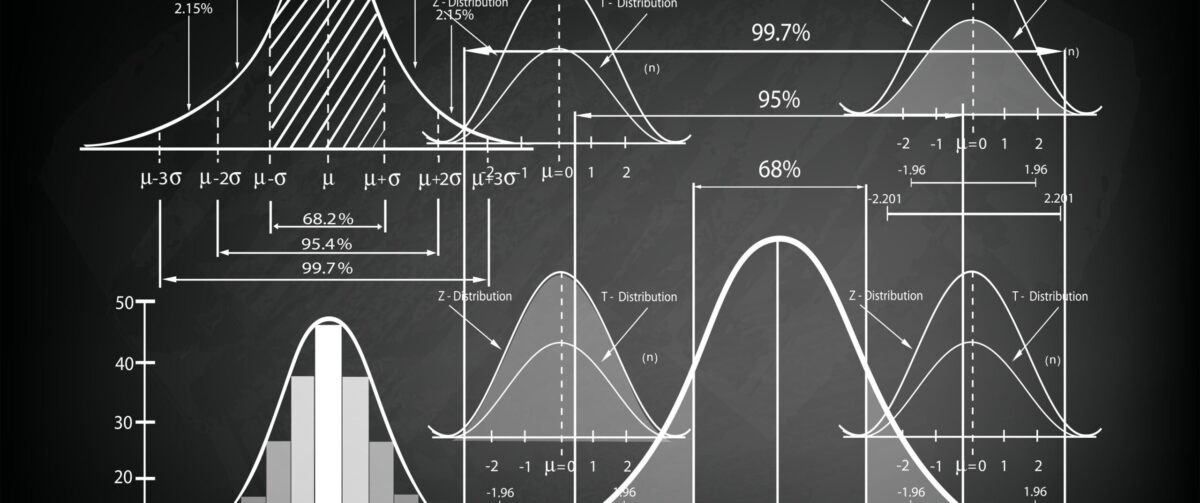

Why Statistical Knowledge in Lean Six Sigma Certification is Crucial for Success

Lean Six Sigma isn’t just about tools; it’s a data-driven mindset rooted in statistical knowledge. Learn how mastering statistics fuels sustainable improvements and success in Lean Six Sigma projects.

How to Choose the Right Lean Six Sigma Certification for You

Lean Six Sigma certifications are powerful tools for professionals aiming to enhance their careers, but choosing the right certification level can be challenging. Whether you are just starting out or looking to solidify your leadership in process improvement, each certification level — Yellow Belt, Green Belt, and Black Belt — offers distinct advantages and prepares…

Lean Six Sigma Certification: How It Can Boost Your Career

In today’s competitive job market, standing out and advancing your career can be challenging. One certification that continues to gain momentum across industries is Lean Six Sigma. Whether in manufacturing, healthcare, or finance, Lean Six Sigma certification equips professionals with valuable skills that enhance problem-solving abilities, improve leadership potential, and increase earning power. By mastering…

How Measurement Systems Management (MSM) Enhances IATF 16949 Compliance and Corporate Profitability

In the ever-evolving landscape of automotive manufacturing, the quest for excellence is a constant. Quality assurance, accuracy, precision, and adherence to US and international standards are not mere objectives; they are necessities. In this realm, IATF 16949:2016 stands as the beacon of automotive quality standards. Born from a collaboration of the world’s leading automotive manufacturers…

Announcing the Release of the 6th Edition of The Six Sigma Handbook by Thomas Pyzdek!

Hello Six Sigma Enthusiasts, We are thrilled to announce the release of the latest edition of the invaluable Six Sigma resource – the 6th Edition of The Six Sigma Handbook, authored by Thomas Pyzdek. This edition comes fully updated with the latest advances and knowledge in the field of Six Sigma, promising to be an…

The Power of Six Sigma in Optimizing Call Center Performance: An Experiment

A deep understanding of Six Sigma methodology can revolutionize the way businesses operate and improve their performance. Case in point, a call center’s function, which often faces challenges in agent performance, customer satisfaction, and operational efficiency. To shed light on this, let’s examine an experiment conducted on a call center, using Six Sigma tools to…

Unveiling the Real Essence of Lean Manufacturing: Beyond Superficial Adaptations

It’s an indisputable fact that the world of business is in a perpetual state of flux, with trends, methods, and philosophies emerging at an unprecedented rate. One of these philosophies that have caught the attention of organizations worldwide is Lean Manufacturing. However, as I recently found out, some firms seem to misunderstand the core tenets…

A Paradigm Shift in Healthcare: Embracing Six Sigma and Lean Manufacturing Principles

Sunday papers often make for light reading, but an article I stumbled upon on, compelled me to think deeply. Titled “Don’t Let a Hospital Make You Sick,” the piece was brimming with startling facts about healthcare practices that are unfortunately more common than most people realize. The Unsettling Reality of Healthcare Errors The article unearthed…